3D printing services

- Available 3D printing technologies HP MJF, FDM, SLA

- Over 40 available materials

- Prototyping and mass production

- Express production within 10 days

Order 3D printing

STEP | STP | SLDPRT | STL | IPT | 3DXML | CATPART | PTC | PRT | SAT

All downloads are secure and confidential

Let's try it now by following few steps

1. Upload CAD files

To get started, simply upload your 3D/CAD file

We can accept the following files:

- SolidWorks (.sldprt)

- ProE (.prt)

- IGES (.igs)

- STEP (.stp)

- ACIS (.sat)

- Parasolid (.x_t or .x_b)

- .stl files

2. Choose a process

First, select the required manufacturing process. Your project will be analyzed by engineers.

Within a few hours, we will send you a Manufacturability Analysis Report (DFM) for the part and the price in real time.

3. Order your parts online

Once you have reviewed your offer and placed an order, paying for it on the secure payment platform and we will begin the production process.

4. Get your parts

During the agreed period of time, you will receive the ordered parts. You can track your package at any time in your personal account, and also check the status of other orders.

The advantages of working with us

Fast turnaround

By using modern technology to start producing parts, we reduce the time required to prepare a quotation, as well as reduce the time to prepare production. Availability of free production capacities at all times.

Precision

We work with both millimeters and inches. The quality of our network of CNC machines allows us to achieve the specified machining precision. We have a selection system of manufacturers that are suitable for you.

Quality control

Our accredited quality control laboratory checks all the parts you order. We issue quality certificates if necessary.

Fast delivery

We deliver parts in Ukraine, as well as anywhere in Europe. You can choose different delivery options that are convenient for you

3D printing materials

- PA11

- PA12

- TPU (polyurethane), optional

Standard materials:

- ABS

- ABS+

- ABS ECO

- ABS FLEX

- ABS PRO

- PETG (COPET)

- PCTG

- PLA

- PLA+

- PLA-HT

- PLA-LW

- T-PLA

- HIPS

- SAN

- SLICE SUPPORT

Engineering plastics:

- ELASTAN

- TPU

- PET

- PC

- NYLON

- PA

- ASA

- PBT

- ABS/PC

- PP

- WAX-FILAMENT

Composite materials:

- ABS/PC

- ABS PRO CCF (CARBON FIBER)

- ABS PRO CGF (GLASS FIBER)

- PETG (COPET)-CG GRAPHITE

- PETG (COPET)-CCF (CARBON FIBER)

- PLA-COFFEE

- PLA-CCU COPPER

- PLA-CNI NICKEL

- PLA-СG+ GRAPHITE

- PLA-CCF (CARBON FIBER)

- ELASTAN D70 CCF (CARBON FIBER)

- TPU CONDUCTIVE

- NYLON-CCF (CARBON FIBER)

- PA12 ССF (CARBON FIBER)

- Standard

- Industrial (not subject to changes in the range from -45 ˚С to +225 ˚С)

- Enhanced strength (mechanical properties such as injection molding ABS)

- Dental (heat resistant)

- Burnout (for the production of investment casting molds)

- Injection molding (for printing very small parts and producing precise templates for vacuum casting)

- Engineering (Viscosity: 440 cPs, Shore D:86)

- Rubber-like (for elastic products)

Surface finish options after 3D-printing

No processing

After cooling, the parts go through a standard powder cleaning process. After that, the part is ready for use.

Painting

The printed parts after cleaning are gray and have a rough surface. If necessary, we paint in the desired color.

Grinding:

Graphite blasting with glass spheres available for smooth surface finish

No processing

In most cases, FDM printed parts do not require any finishing, except where supports have been provided. Since the materials (filaments) are initially available in a wide range of colors, parts are initially printed in the desired color.

Grinding

The method of abrasive processing of solid surfaces of printed parts with the aim of obtaining a smooth surface. It is usually used to achieve a smooth surface of a part or prepare it for applying a paint coating.

Painting

Applying a paint coating to the solid surfaces of printed parts after their cleaning and preparation for painting in the desired color. It is used to achieve the desired color of the part’s surface, provide protection against environmental influences, etc.

Chemical treatment

The process of treating printed products with chemical reagents to achieve gloss, smooth out layers, or alter the mechanical properties of the material from which the part is printed.

No processing

The support material is removed and the parts are cleaned.

Custom Finish

Additional processing and finishing on request.

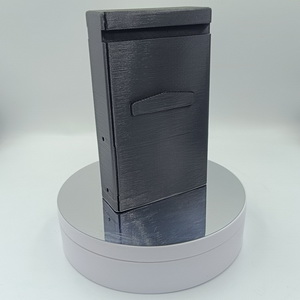

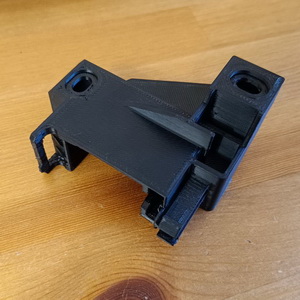

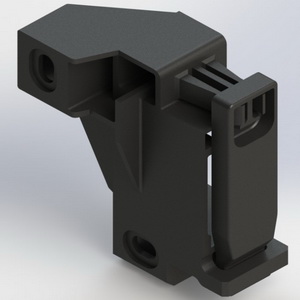

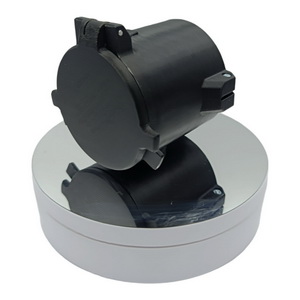

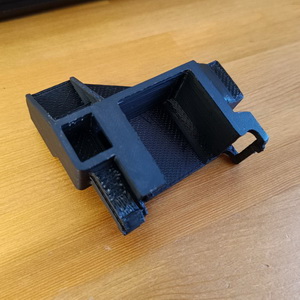

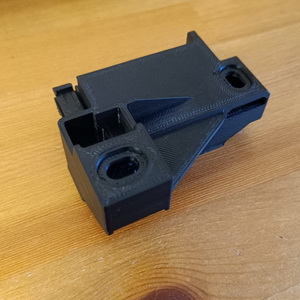

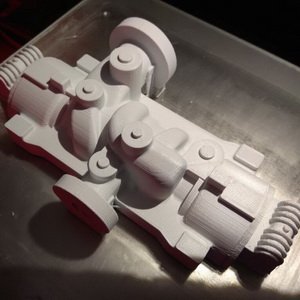

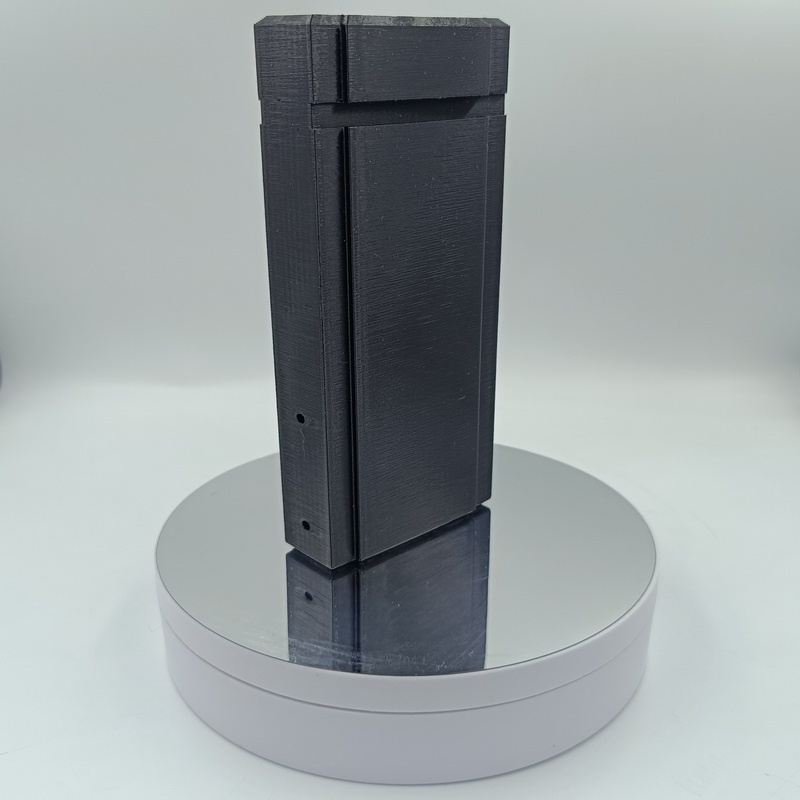

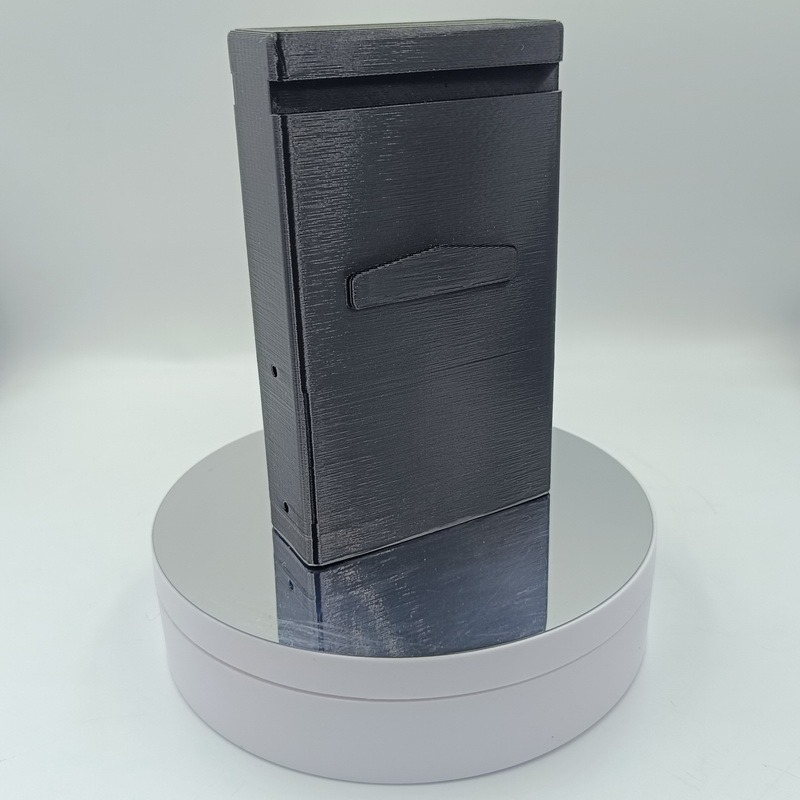

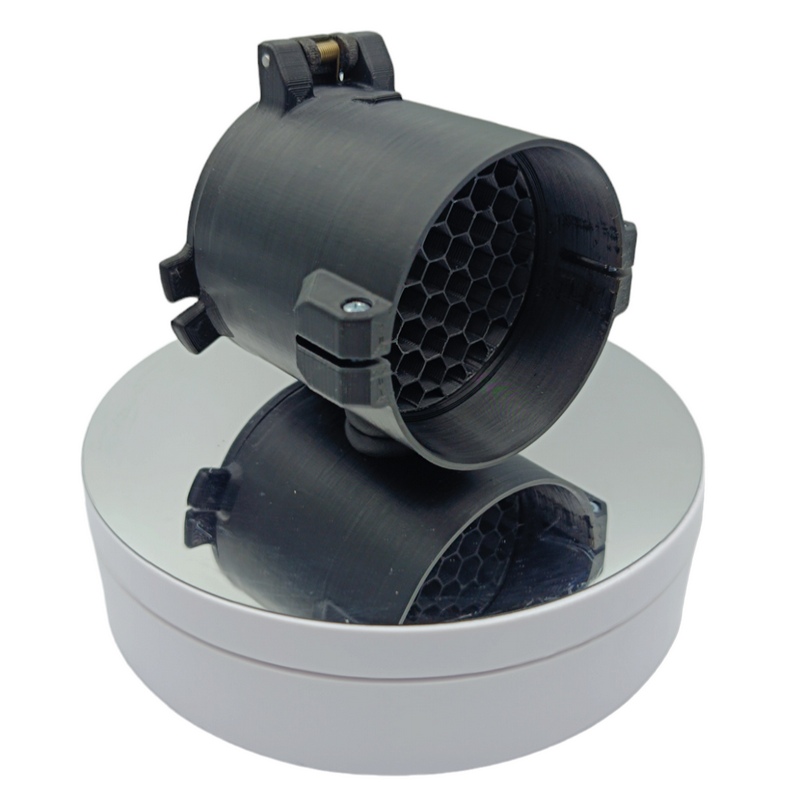

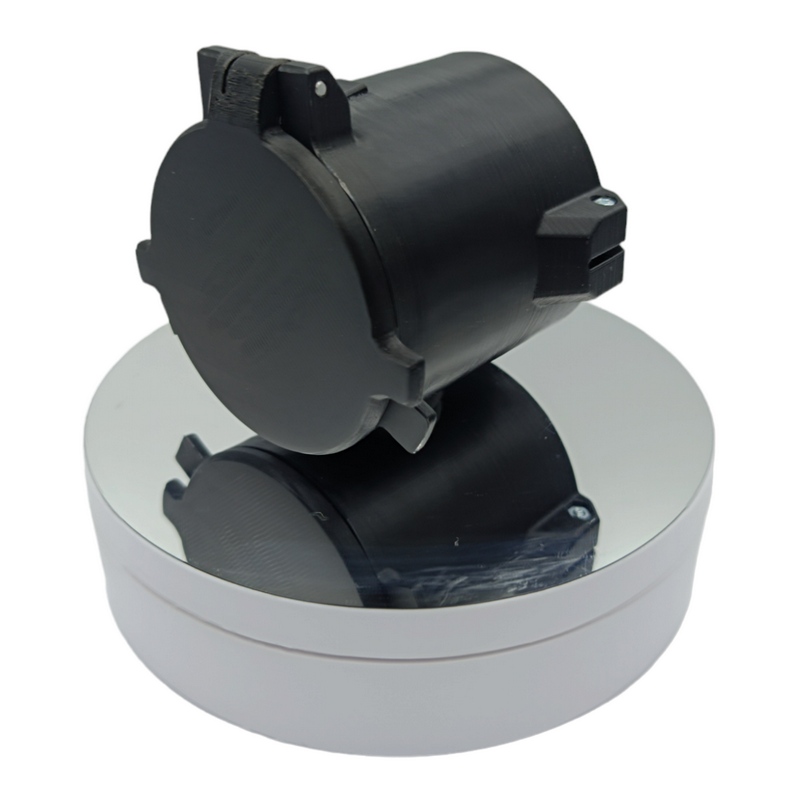

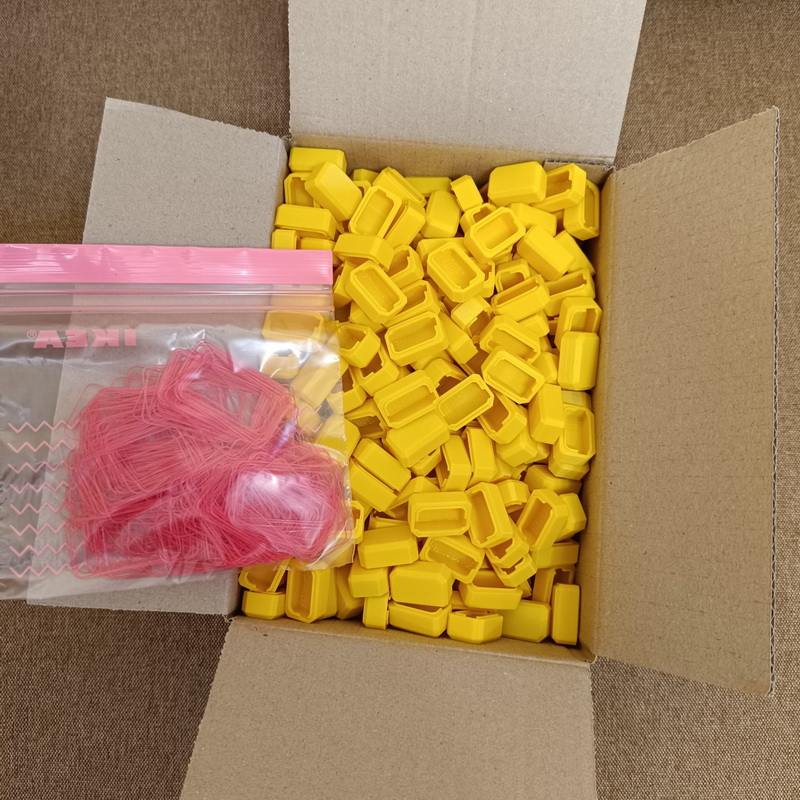

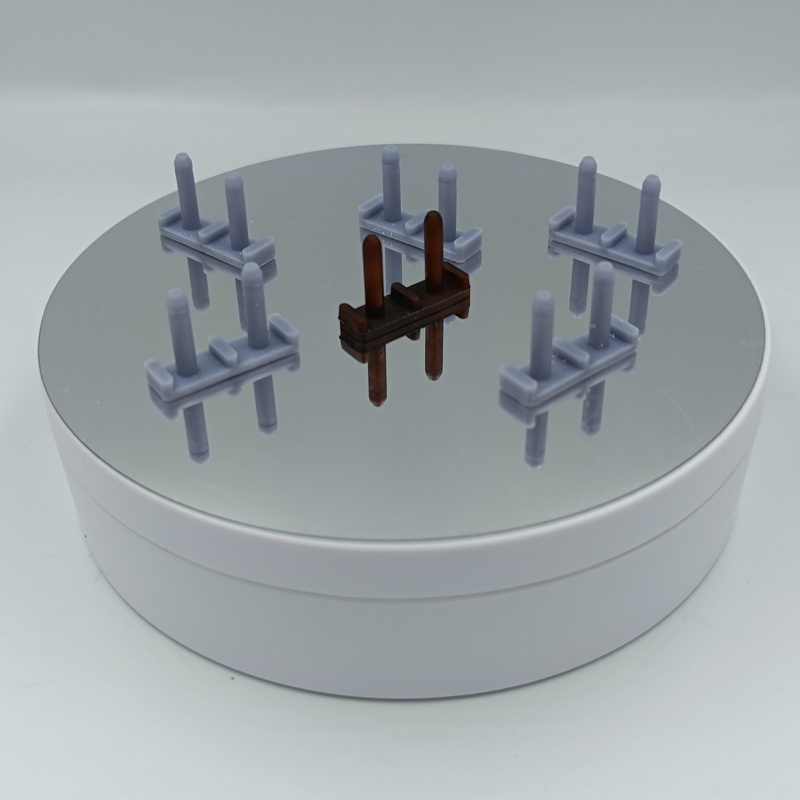

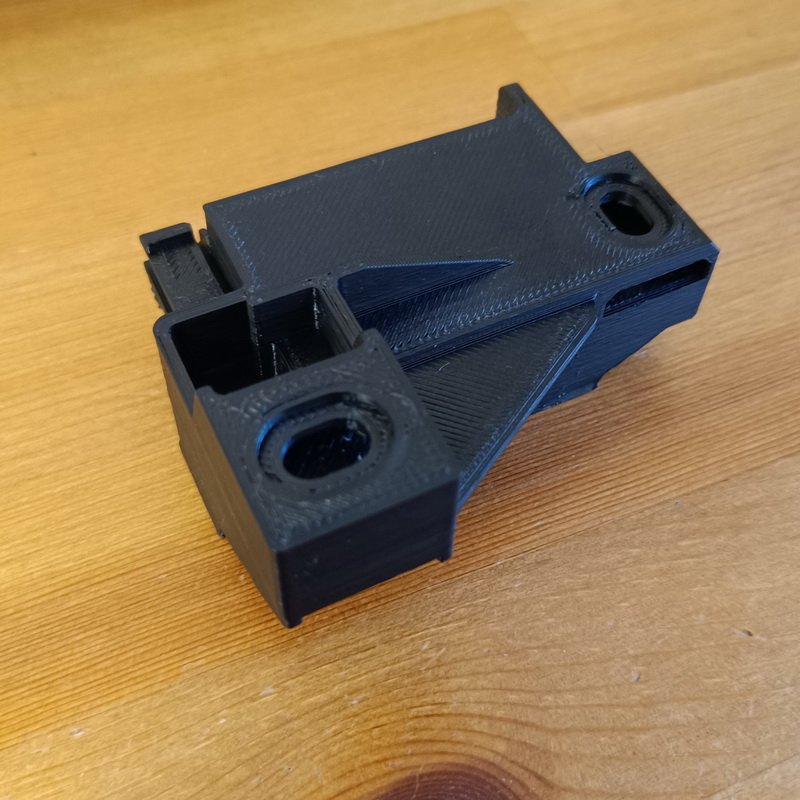

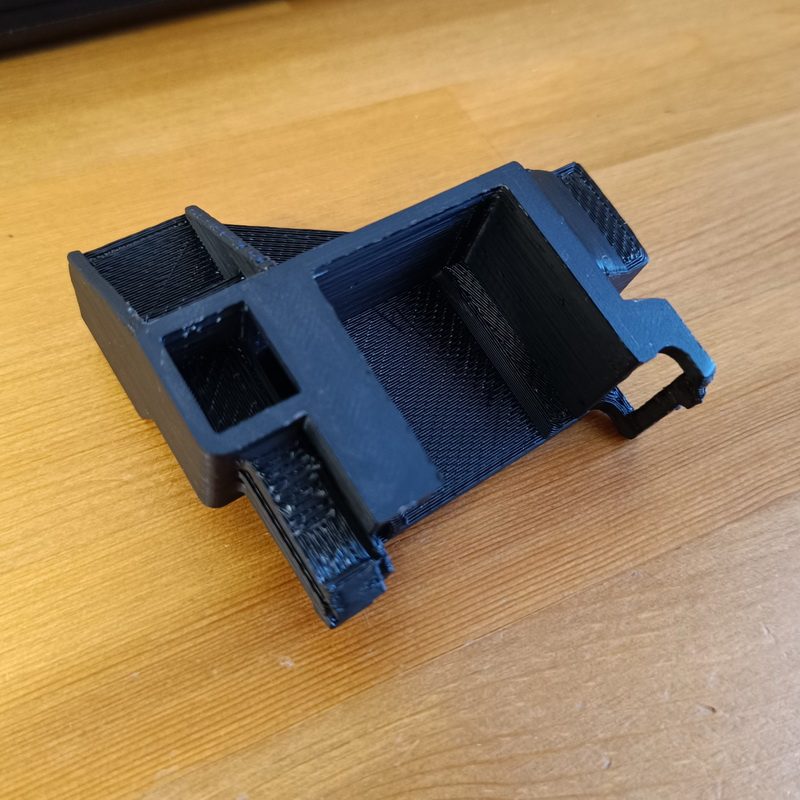

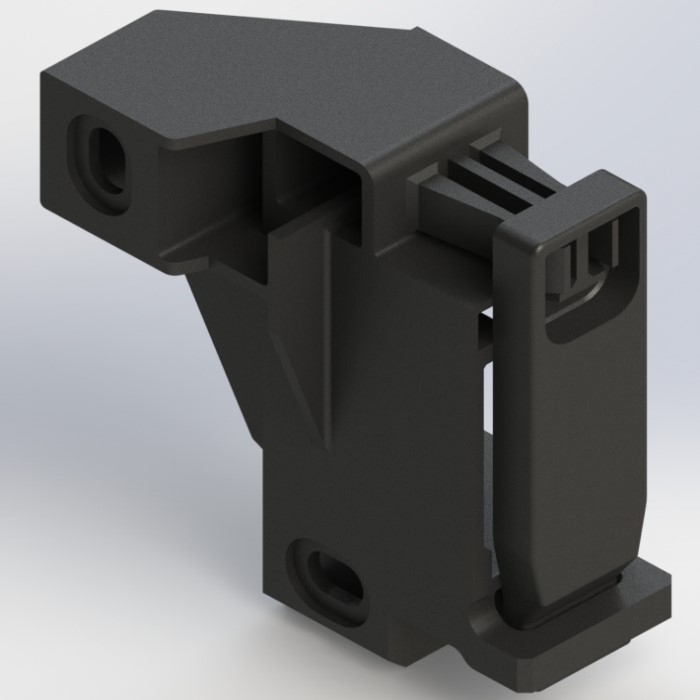

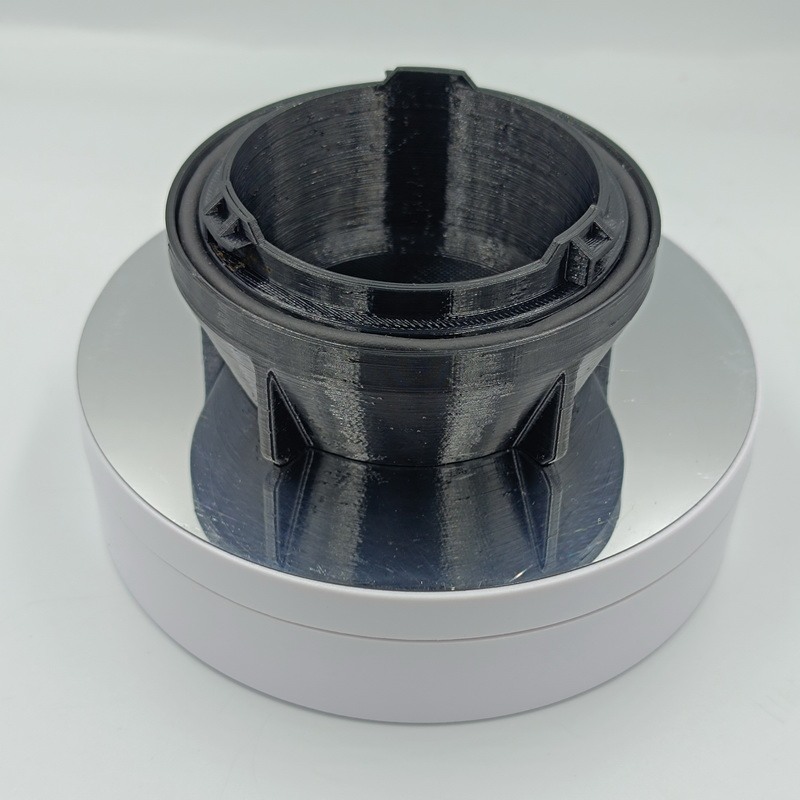

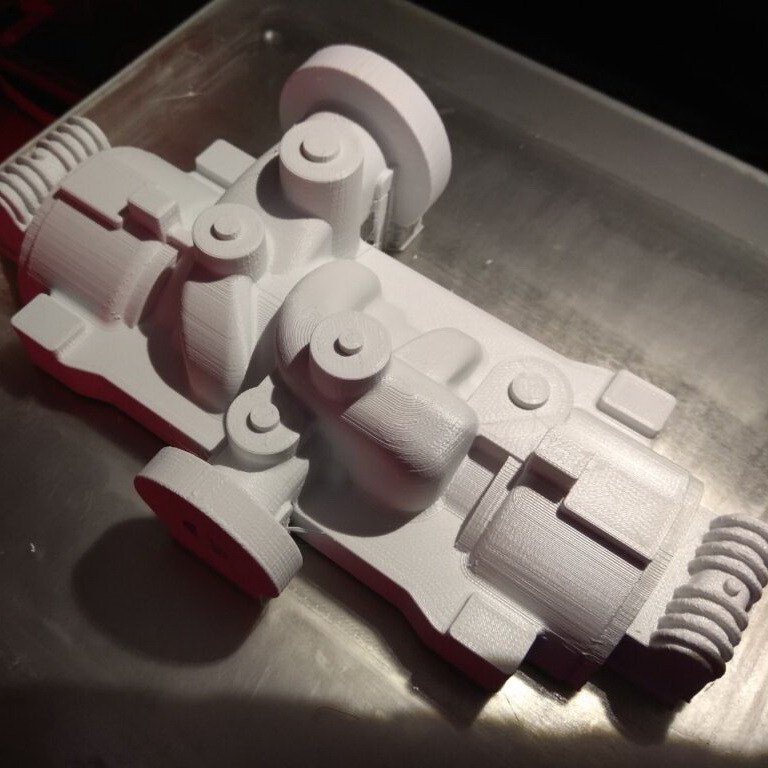

Gallery of 3D printed parts

Comparison of 3D printing technologies

Lead time

3 days

5 days

7 days

Print volume

380 x 270 x 380 mm

500 х 500 х 500 mm

300 х 298 х 345 mm

Minimum layer thickness

~0,08 mm

~0,05-0,3 mm

0,02 mm

Minimum object size

0,5 mm

10 mm

0,2 mm

Tolerances

±0,3% (±0,2 mm)

±0,5% (±0,5 mm)

±0,5% (±0,15 mm)

Description

A technology that allows the production of highly accurate and durable parts at high print speeds, especially when compared to other powder bed printing technologies.

Widely known for its large selection of materials, precision and ability to print large parts.

A technology that allows the production of extremely precise, high-resolution parts.

Order parts now

CNC machine tools online:

500+

3D printers online:

100+

All downloads are secure and confidential