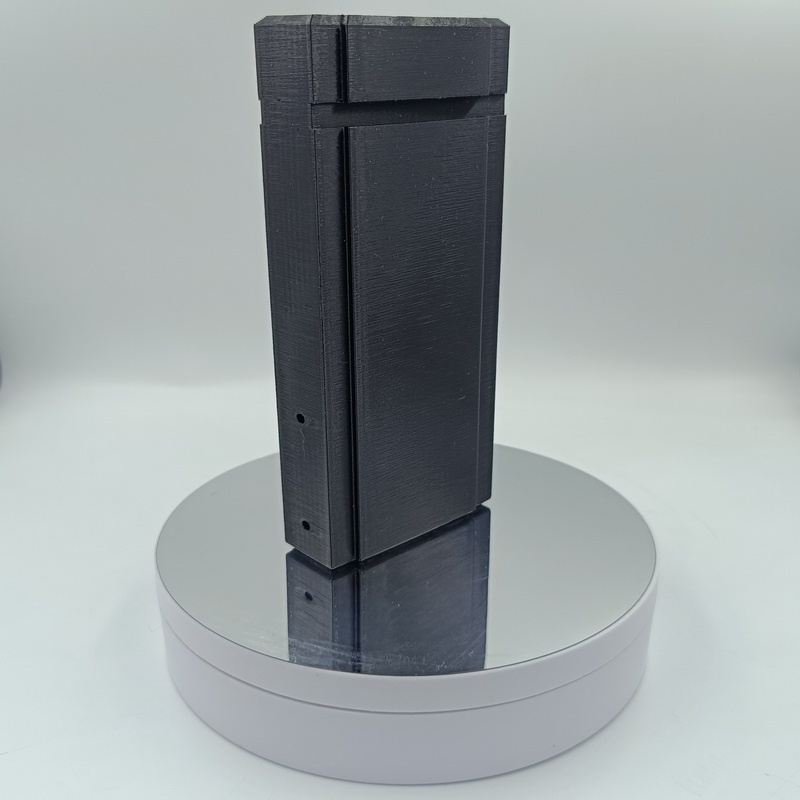

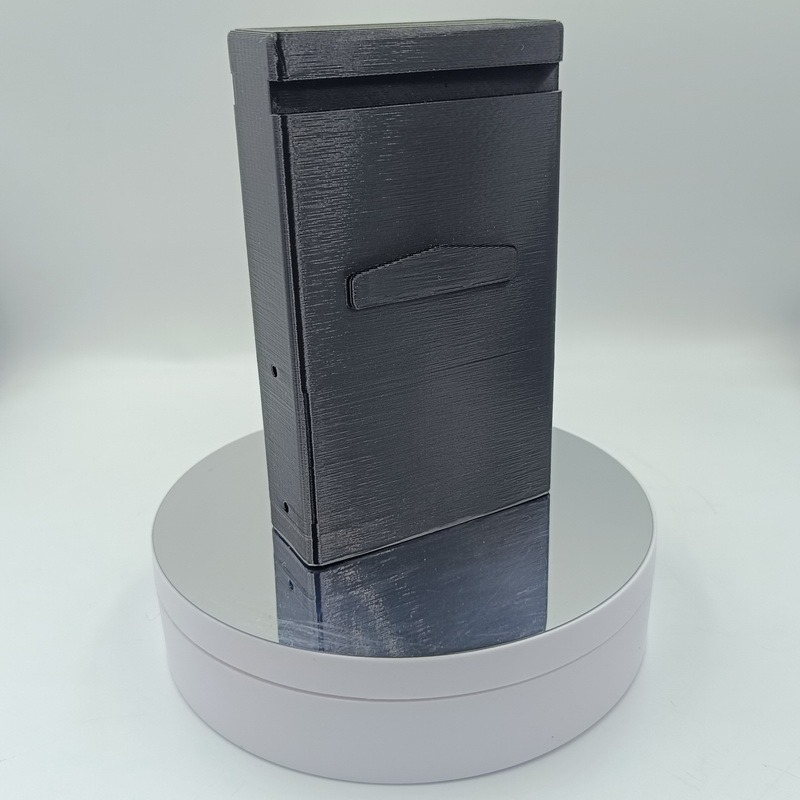

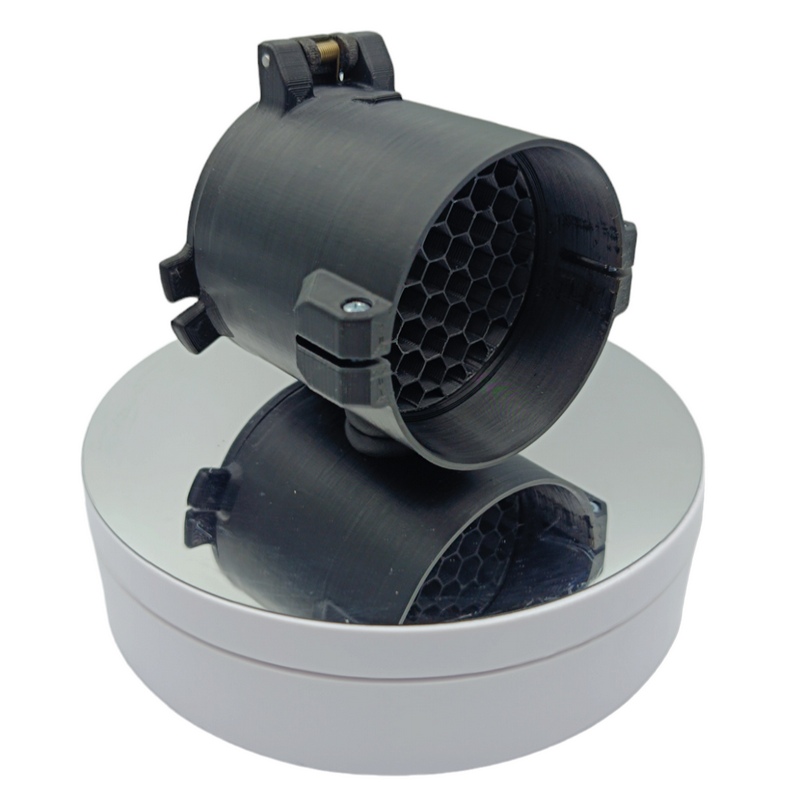

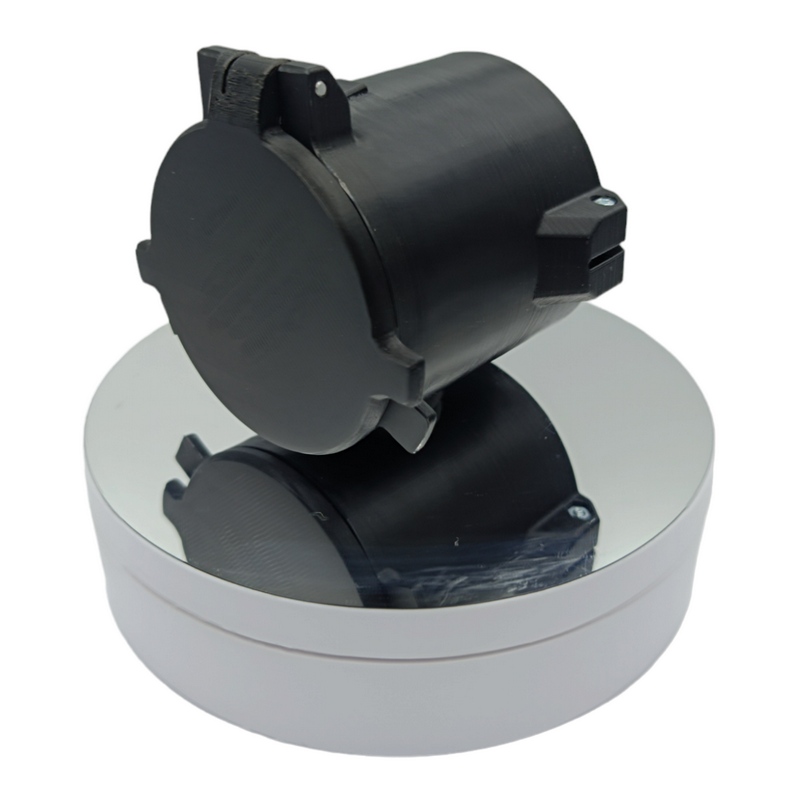

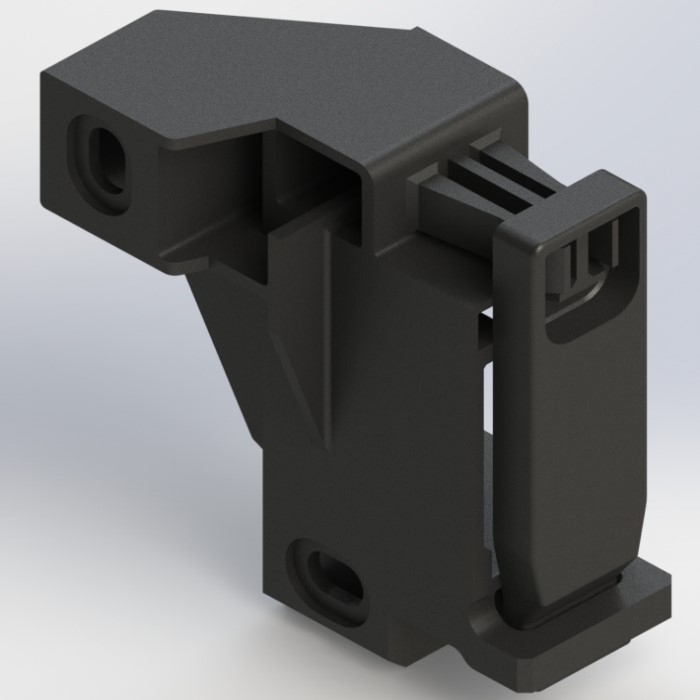

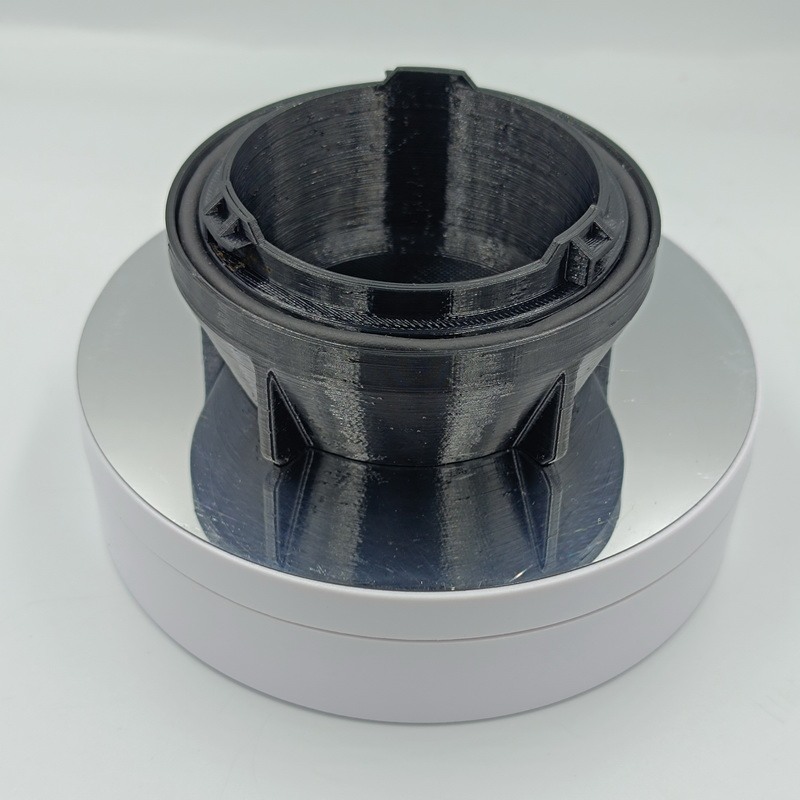

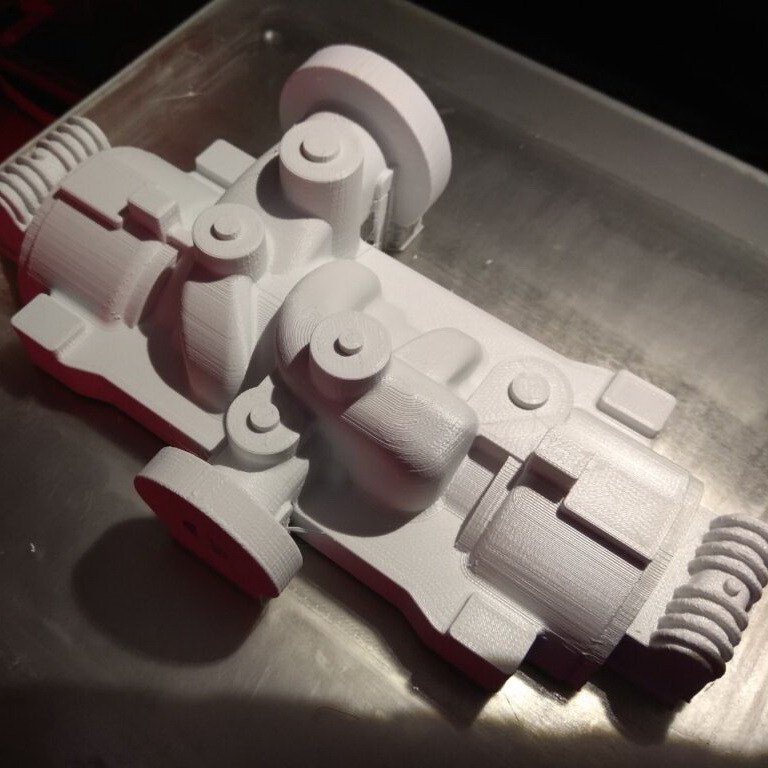

Design for FDM 3D Printing

Design for FDM 3D Printing – Tips For successful 3D printing using Fused Deposition Modeling (FDM) technology, your 3D model needs to meet specific requirements to ensure accurate and high-quality printing. Key design considerations for 3D models intended for FDM 3D printing are as follows: File Format The 3D model should be in a format […]