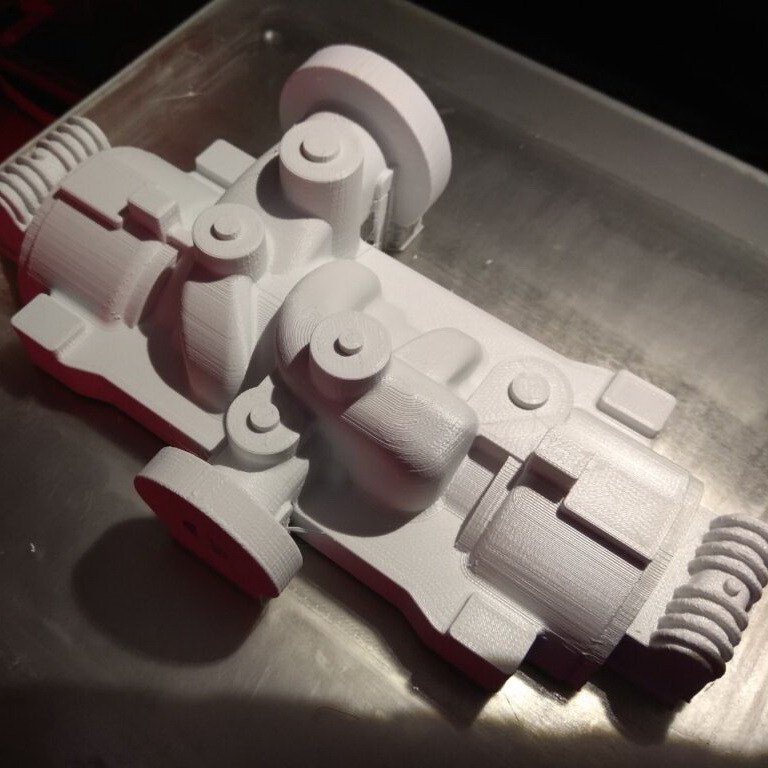

Comparison of SLA and FDM 3D printing technologies

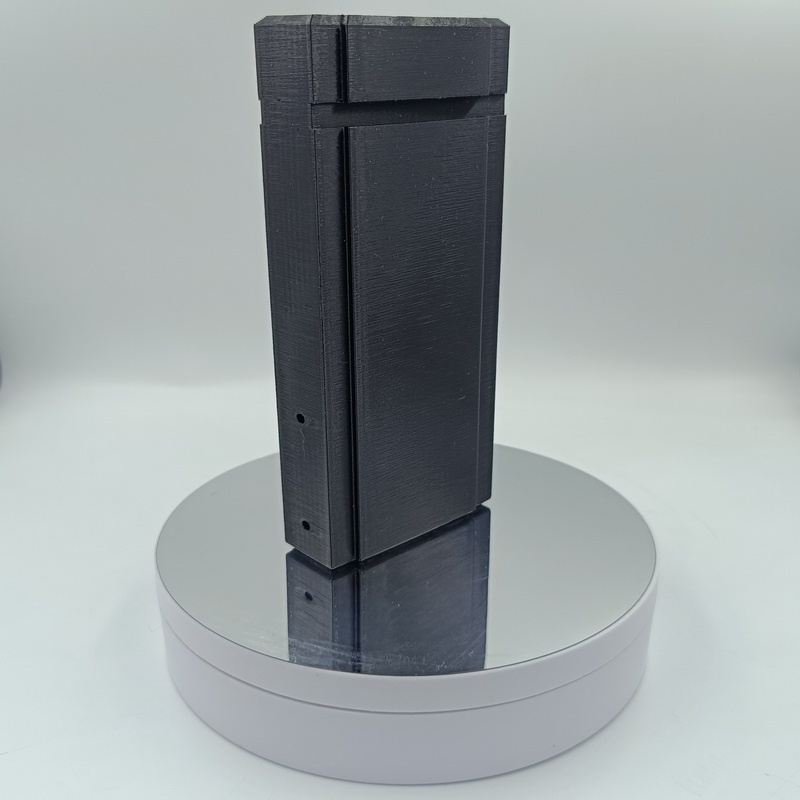

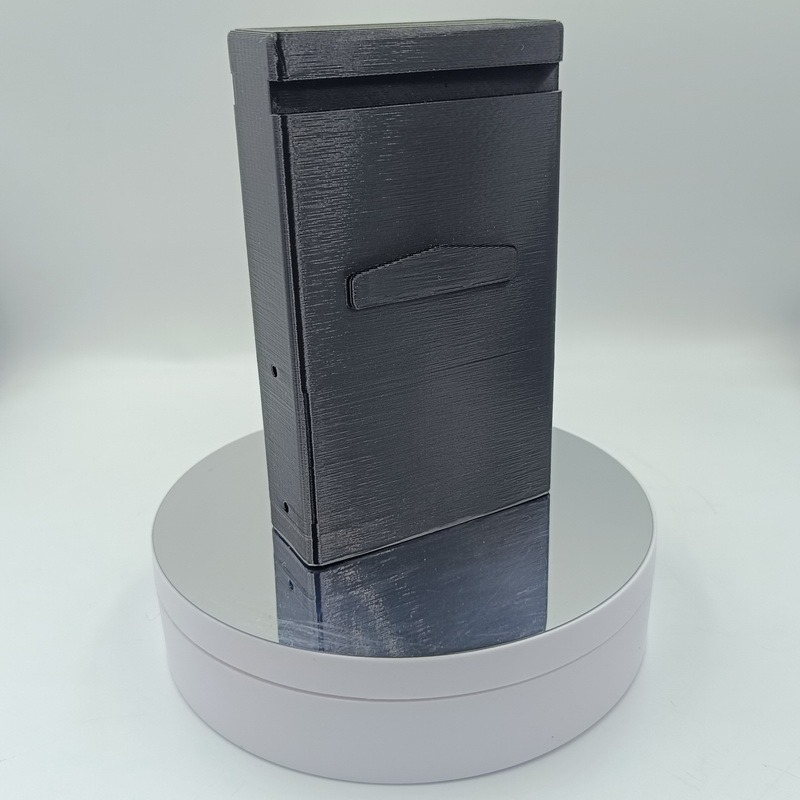

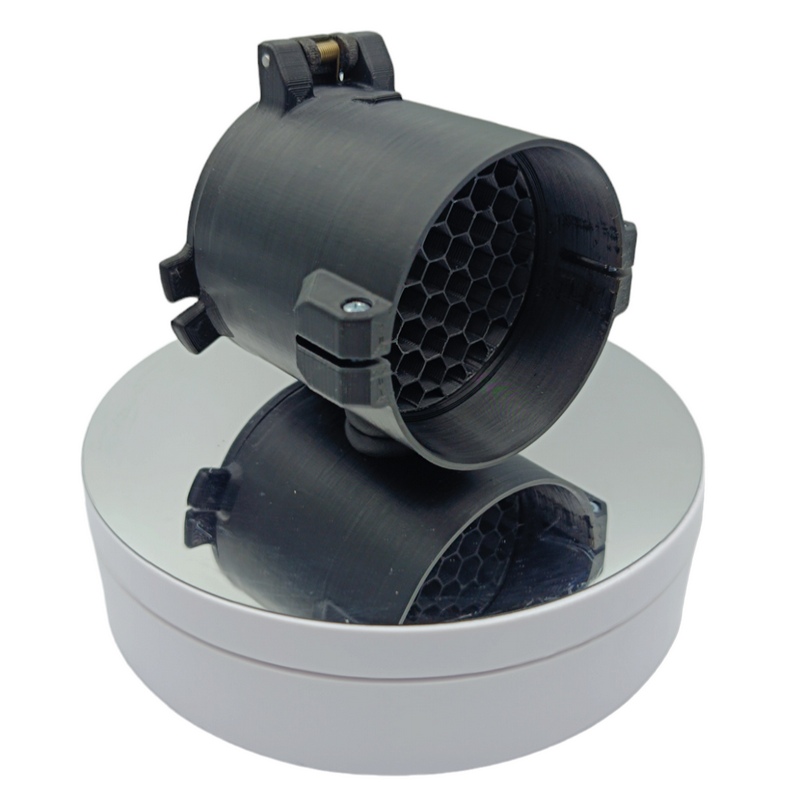

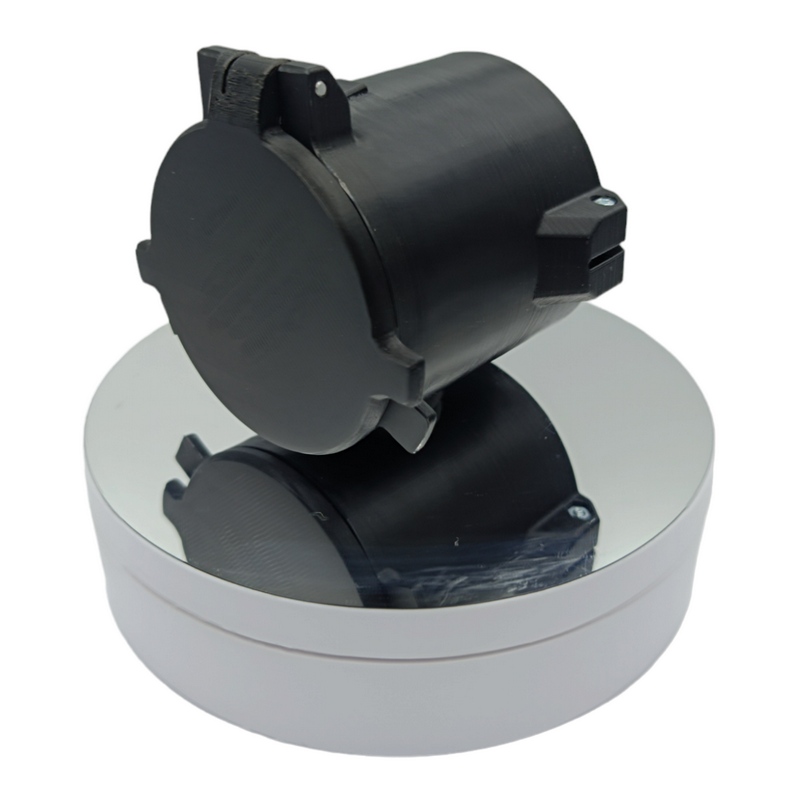

Comparison of SLA and FDM 3D printing technologies by main parameters. This will allow us to understand the advantages and disadvantages of each of these technologies. SLA (Stereolithography) and FDM (Fused Deposition Modeling) are two of the most popular 3D printing technologies. While both are additive manufacturing processes, they differ in the way they create […]

Comparison of SLA and FDM 3D printing technologies Read More »