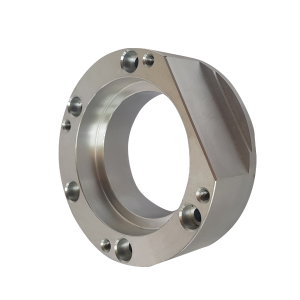

CNC Machining Services

CNC Machining:

- CNC turning, milling, drilling, boring and carousel machining

- Huge selection of processed materials

- Express production

Start CNC Machining

PDF | DXF| STEP | STP | SLDPRT | STL | IPT | 3DXML | CATPART | PTC | PRT | SAT

All downloads are secure and confidential

Order CNC Machining Online

We provide services for metal machining and specialize in the production of metal products according to individual projects. We perform work of any complexity, as well as large volumes of ordered products using different materials. Within hours, we will send you a Manufacturability Analysis Report (DFM) of the part and a real-time price of the part. We then organize the production of the part and perform an independent quality control in our accredited laboratory, in order to guarantee you the quality of the parts produced for you.

To request a quotation for CNC machining, simply upload files with drawings, 3D models or hand-drawn sketches – this is enough for us to start preparing to manufacture your parts.

Let's try it now by following few steps

1. Upload CAD files

To get started, simply upload your 3D/CAD file

We can accept the following files:

- SolidWorks (.sldprt)

- ProE (.prt)

- IGES (.igs)

- STEP (.stp)

- ACIS (.sat)

- Parasolid (.x_t or .x_b)

- .stl files

2. Choose a process

First, select the required manufacturing process. Your project will be analyzed by engineers.

Within a few hours, we will send you a Manufacturability Analysis Report (DFM) for the part and the price in real time.

3. Order your parts online

Once you have reviewed your offer and placed an order, paying for it on the secure payment platform and we will begin the production process.

4. Get your parts

During the agreed period of time, you will receive the ordered parts. You can track your package at any time in your personal account, and also check the status of other orders.

Advantages of working with us:

Fast turnaround

By using modern technology to start producing parts, we reduce the time required to prepare a quotation, as well as reduce the time to prepare production. Availability of free production capacities at all times.

Precision

We work with both millimeters and inches. The quality of our network of CNC machines allows us to achieve the specified machining precision. We have a selection system of manufacturers that are suitable for you.

Quality control

Our accredited quality control laboratory checks all the parts you order. We issue quality certificates if necessary.

Fast delivery

We deliver parts throughout Ukraine, as well as anywhere in Europe. You can choose different delivery options convenient for you.

Materials for CNC machining

- Steel 1.0038 / S235JR

- Steel 1.0503/С45

- Steel 1.0511/С40

- Steel 1.0570/S355J2G3

- Steel 1.7131/16MnCr5

- Steel 1.7218/25CrMo4

- Steel 1.7225/42CrMo4

- and others on request…

- Stainless steel 303 / 1.4305 / X10CrNiS18-9

- Stainless steel 304/1.4301/X5CrNi18.10

- Stainless steel 304L/1.4307/X2CrNi18-9 304L/1.4307/X2CrNi18-9

- Stainless steel 316L/1.4404/X2CrNiMo17-12-2

- Stainless steel 316Ti/1.4571/X6CrNiMoTi17-12-2

- Aluminium 2007 / 3.1645 / Al-CuMgPb

- Aluminium 2017А/3.1325/Al-Cu4Mg

- Aluminium 6060/3.3206/Al-MgSi

- Aluminium 6061/3.3211/Al-Mg1SiCu

- Aluminium 6082/3.2315/Al-Si1Mg

- Aluminium 7075/3.4365/Al-Zn6MgCu

- E-Cu57/2.0060/E-Cu58/2.0065

- Brass МС58/2.0401/CuZn39Pb3

- ABS

- Acrylic

- Polycarbonate

- PEEK

- Polypropylene

- POM

- PTFE

- and others on request…

Surface finish options after machining

All parts are CNC treated after machining to remove sharp edges and burrs after machining. We also remove chips from hard-to-reach areas.

- Цинкование гальваническое

- Химическое никелирование

- Оксидирование

- Анодирование алюминия: натуральное и цветное

- Polishing

- Sand blasting and shot blasting

- Liquid and powder painting

- Hardening and tempering

- Normalization

- Annealing

- and others on request…

Additional post-processing and finishing on request.

What is CNC?

Basics of CNC machining

Machining with a CNC (numerical control) machine is the machining of metal or other machined material by cutting. Metal cutting is based in most cases on the principle of rotating the cutting tool or workpiece, in combination with the movement along a defined path of the workpiece or cutting tool. What and how to rotate depends on the type of machining, or CNC turning or milling.

Machining on CNC machines allows you to make complex and precise parts with the highest possible requirements that are set for them.

The use of multiple axes in CNC machining makes it possible to produce the most complex shapes, as well as obtain different surface properties.

Learn more about CNC machining in our tutorial.

Order parts now

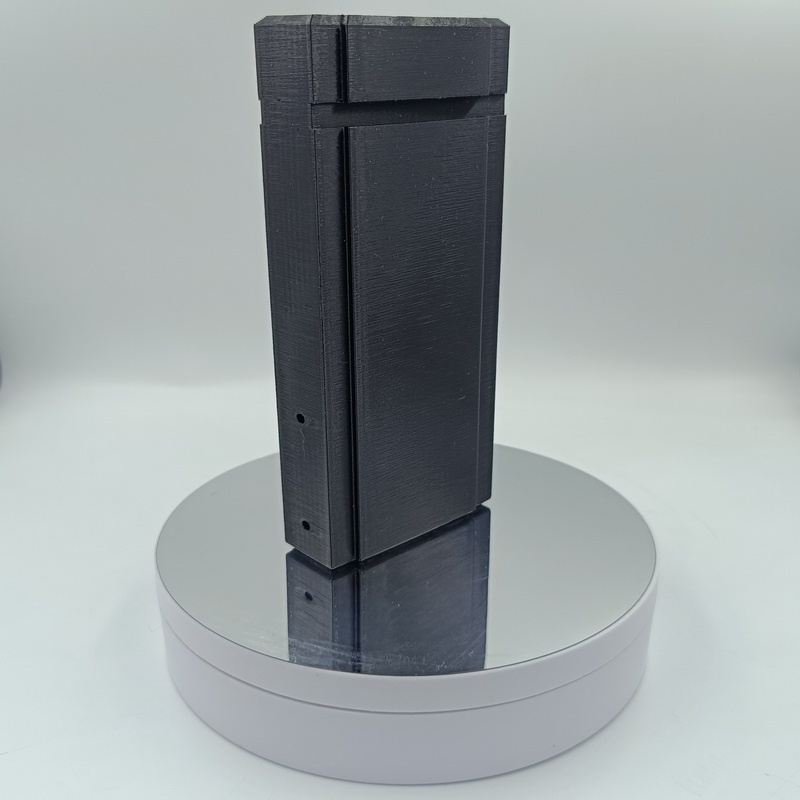

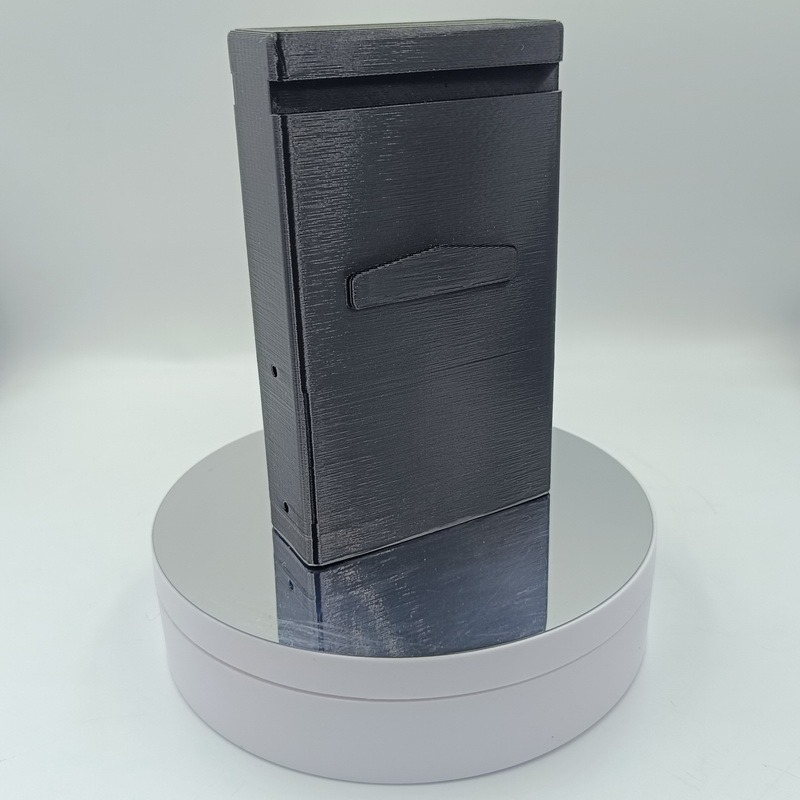

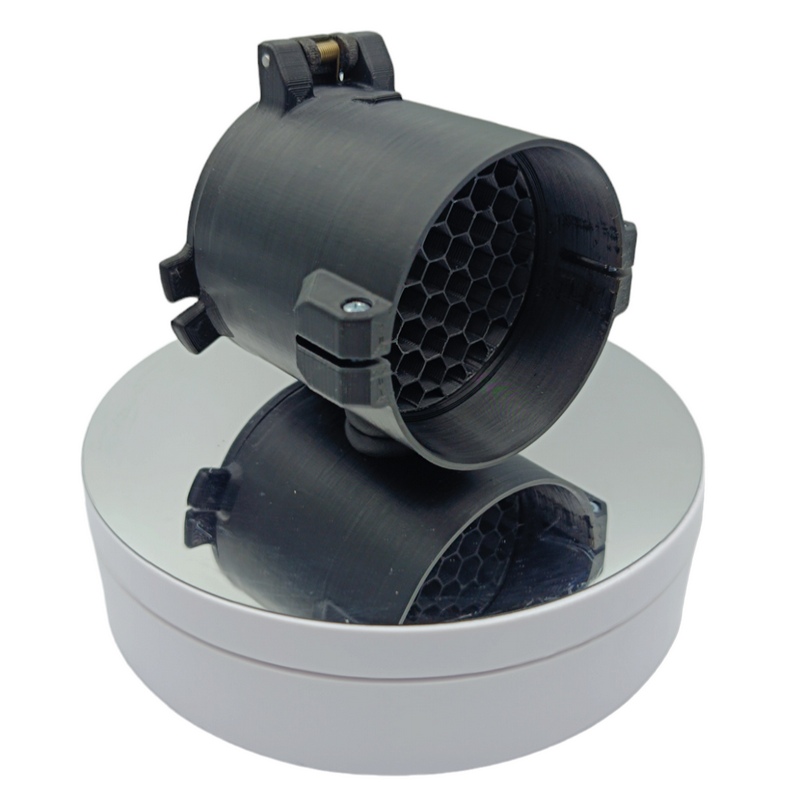

3D printers online:

100+

3D printers online:

500+

All downloads are secure and confidential