HP Multi Jet Fusion (MJF) 3D printing

MJF Services:

- Impeccable quality

- Available materials PA 11, PA 12

- Production from 3 working days

Start 3D printing

STEP | STP | SLDPRT | STL | IPT | 3DXML | CATPART | PTC | PRT | SAT

All downloads are secure and private

3D printing services with HP MJF technology

HP Multi Jet Fusion is a powder-based 3D printing technology that enables fast and precise production of highly-detailed, complex-shaped parts made of thermoplastic powders. The printing process involves the sequential treatment of a layer of thermoplastic powder with a binding agent, followed by fusion with infrared light. After printing, the part is slowly cooled to preserve its mechanical properties.

Compared to SLS technology, parts are printed three times faster and are more durable with stable mechanical properties. This technology is ideal for prototyping and small-batch production, allowing for cost-effective production of parts in small quantities at a fraction of the cost of injection-molded plastics.

Let's try it now by following few steps

1. Upload CAD files

To get started, simply upload your 3D/CAD file

We can accept the following files:

- SolidWorks (.sldprt)

- ProE (.prt)

- IGES (.igs)

- STEP (.stp)

- ACIS (.sat)

- Parasolid (.x_t or .x_b)

- .stl files

2. Choose a process

First, select the required manufacturing process. Your project will be analyzed by engineers.

Within a few hours, we will send you a Manufacturability Analysis Report (DFM) for the part and the price in real time.

3. Order your parts online

Once you have reviewed your offer and placed an order, paying for it on the secure payment platform and we will begin the production process.

4. Get your parts

During the agreed period of time, you will receive the ordered parts. You can track your package at any time in your personal account, and also check the status of other orders.

Advantages of HP MJF

Fast production

Products can be manufactured and shipped in just 3 days, which reduces design time and accelerates the product launch process.

Impeccable quality

MJF technology is a major competitor to injection molding. It allows for printing a large quantity of products in a single printer load.

Quality control

Our Quality Assurance department maintains strict quality control. Our measurement laboratory is certified to the ISO 9001 standard.

Detailing

A horizontal resolution of 1200 DPI with a layer thickness of 80 microns allows for a tolerance range of 100 to 250 microns.

Industrial application

Printed parts can function in various environments under mechanical and other stresses. This technology eliminates the need for expensive model and mold making used in casting production.

Fast delivery

We deliver parts in Ukraine, as well as anywhere in Europe. You can choose different delivery options that are convenient for you

HP MJF 3D Printing Services: Materials

- PA11

- PA12

- TPU (thermoplastic polyurethane), available upon request.

Surface finish options after 3D-printing

The parts go through a standard powder cleaning process after cooling. After that, the part is ready to use.

The printed parts after cleaning have a gray color and a rough surface. If necessary, we perform painting in the desired color.

To achieve a smooth surface, jet polishing with graphite and glass beads is available.

Specify your requirements to us and we will perform post-printing processing.

HP MJF 3D Printing Services - Advantages and Disadvantages

Advantages

High quality and detailing of the parts: high print resolution and absence of support structures allow for precise parts with minimal dimensional deviations.

Excellent strength and good mechanical properties of the printing materials used.

The parts printed using this technology can be used in mass production of products thanks to the high printing speed.

Disadvantages

Limited selection of materials and colors. Only certain materials are available.

Roughness: after printing, parts have a rough surface. To improve the optical properties of the surface, additional mechanical processing is required.

Deformation: large parts tend to deform, for which a support structure needs to be included in the model.

Characteristics and capabilities of HP MJF printing technology

MJF

FDM

SLA

Lead time

3 days

5 days

7 days

Print volume

380 x 270 x 380 mm

500 х 500 х 500 mm

300 х 298 х 245 mm

Minimum layer thickness

~0,08 mm

~0,05-0,3 mm

0,02 mm

Minimum object size

0,5 mm

10 mm

0,2 mm

Tolerances

±0,3% (±0,2 mm)

±0,5% (±0,5 mm)

±0,5% (±0,15 mm)

Description

A technology that allows the production of highly accurate and durable parts at high print speeds, especially when compared to other powder bed printing technologies.

Widely known for its large selection of materials, precision and ability to print large parts.

A technology that allows the production of extremely precise, high-resolution parts.

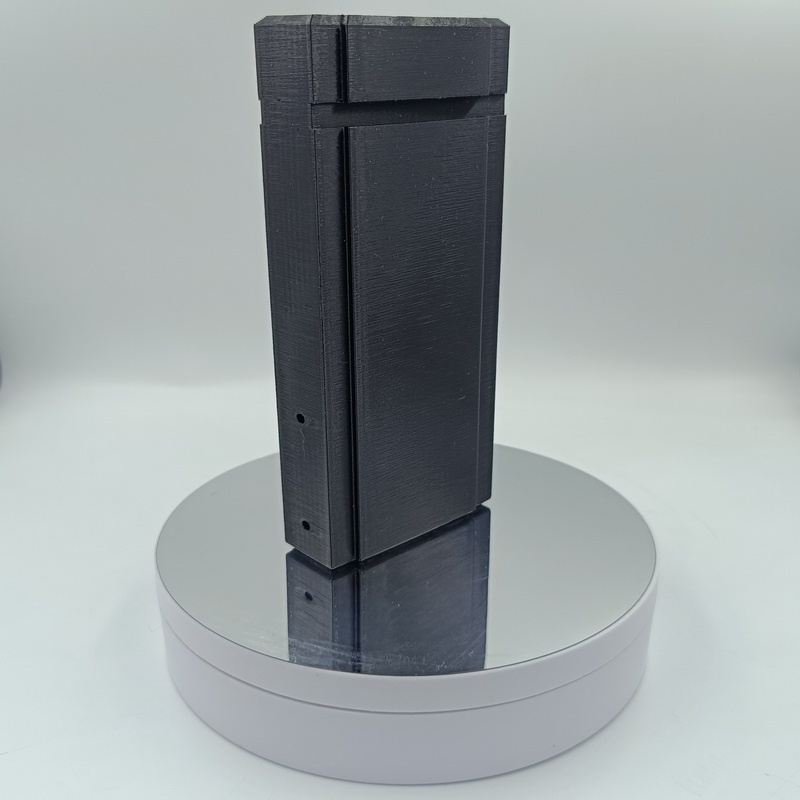

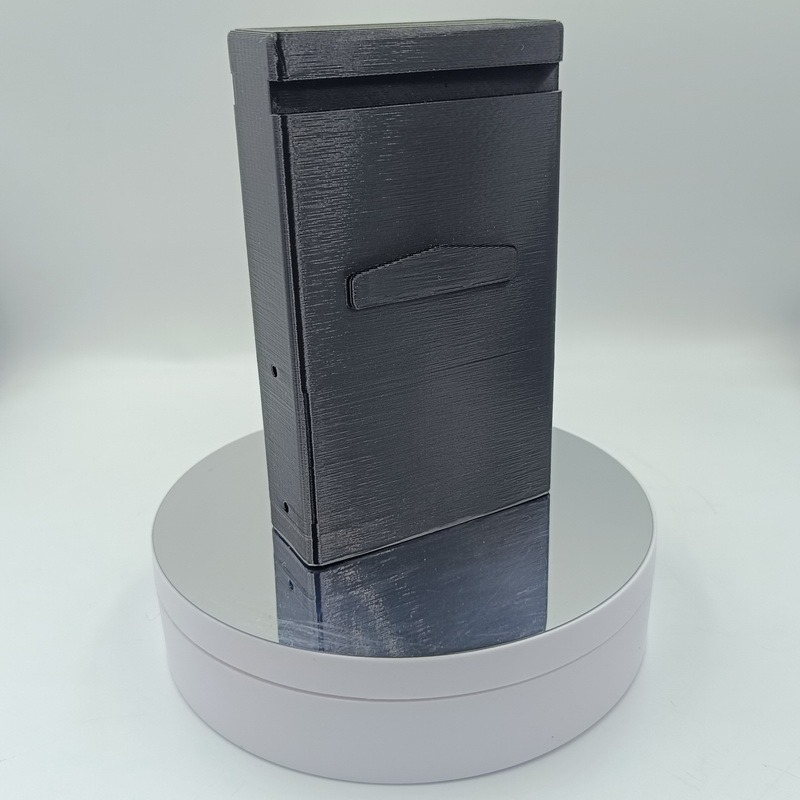

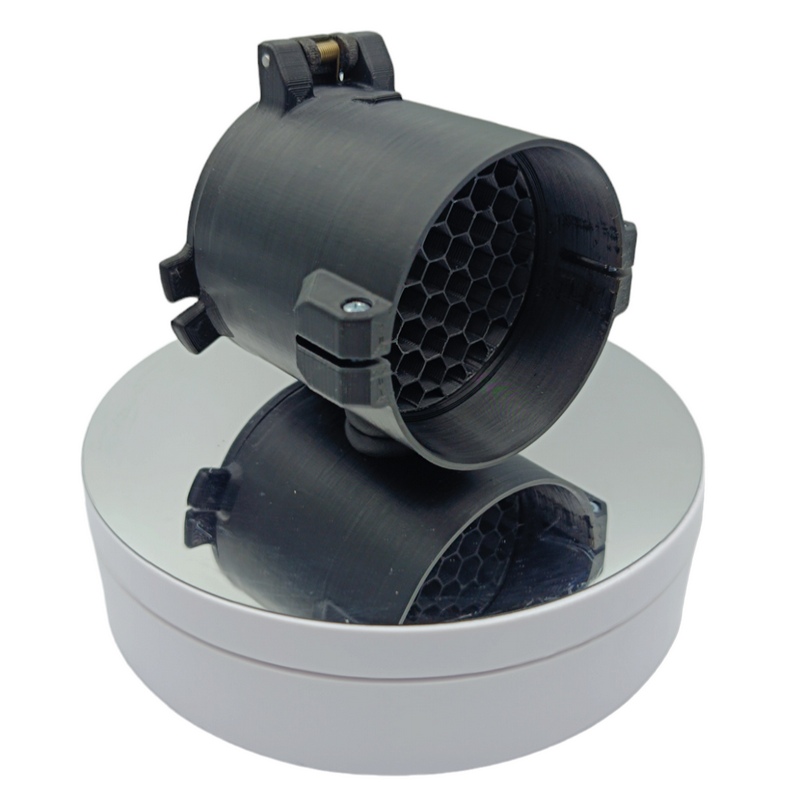

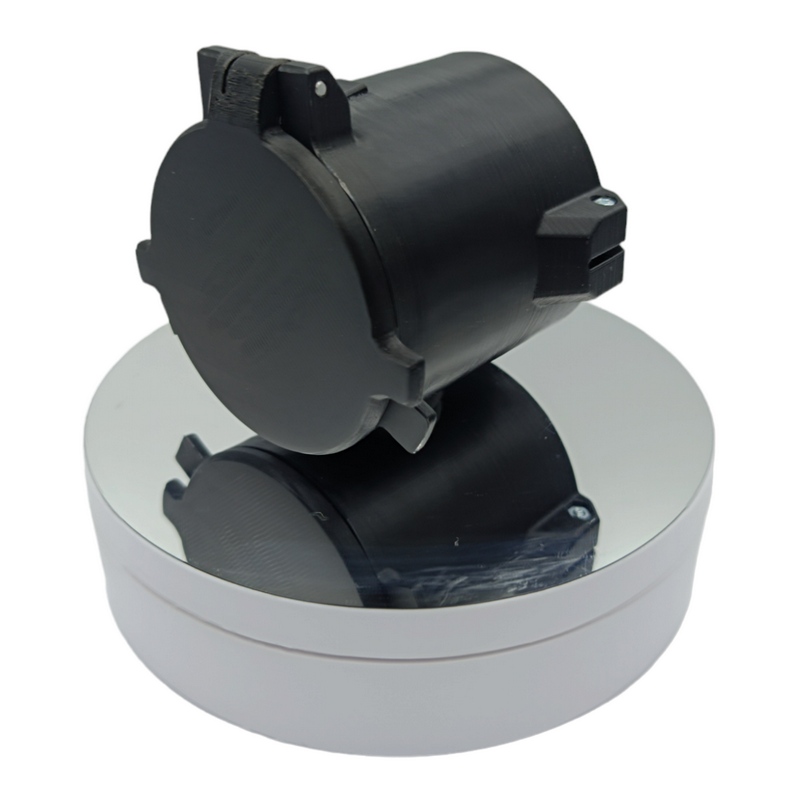

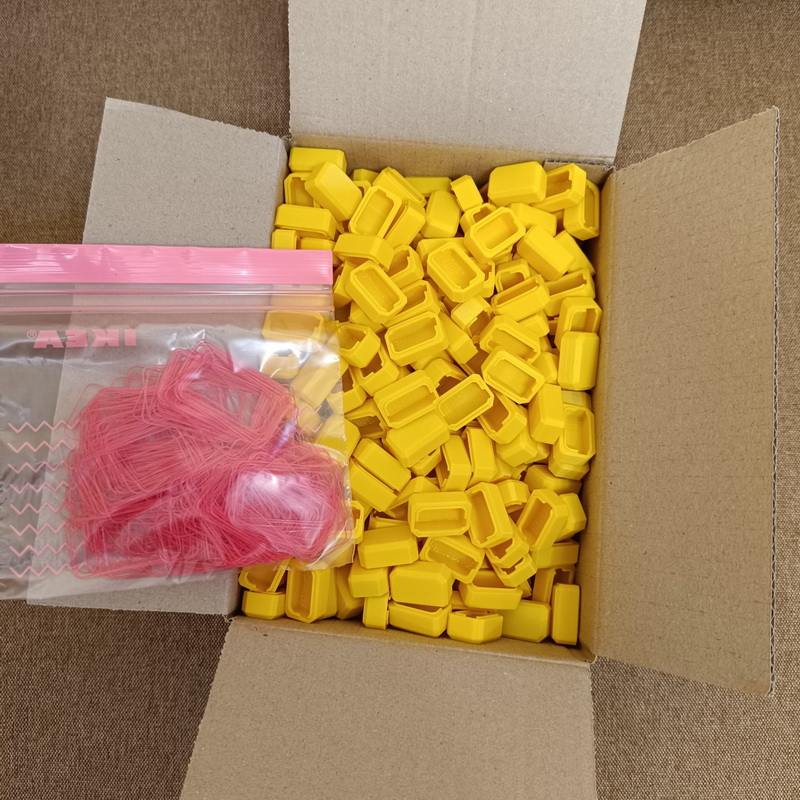

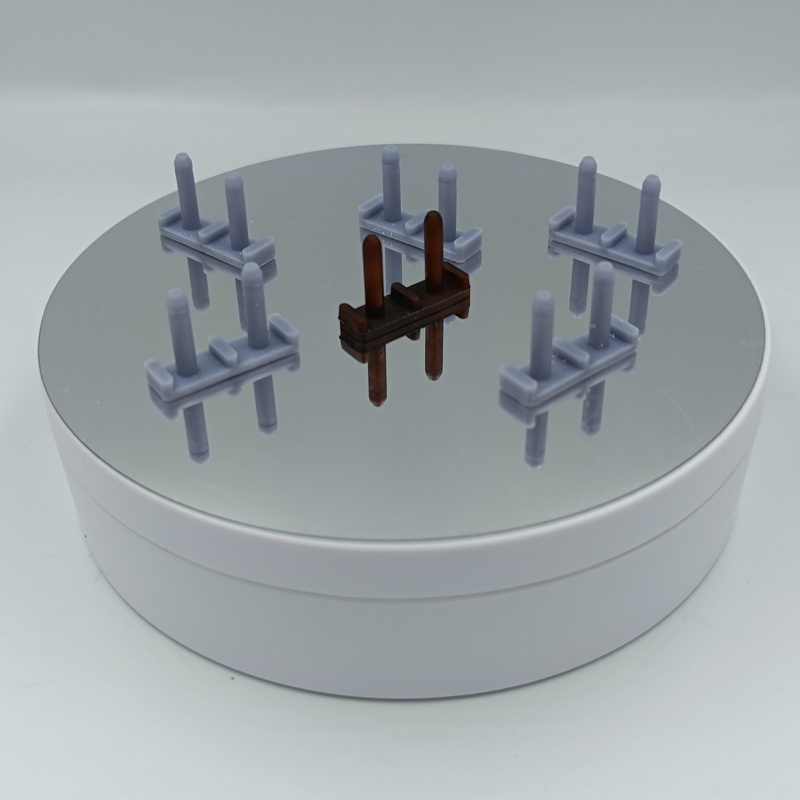

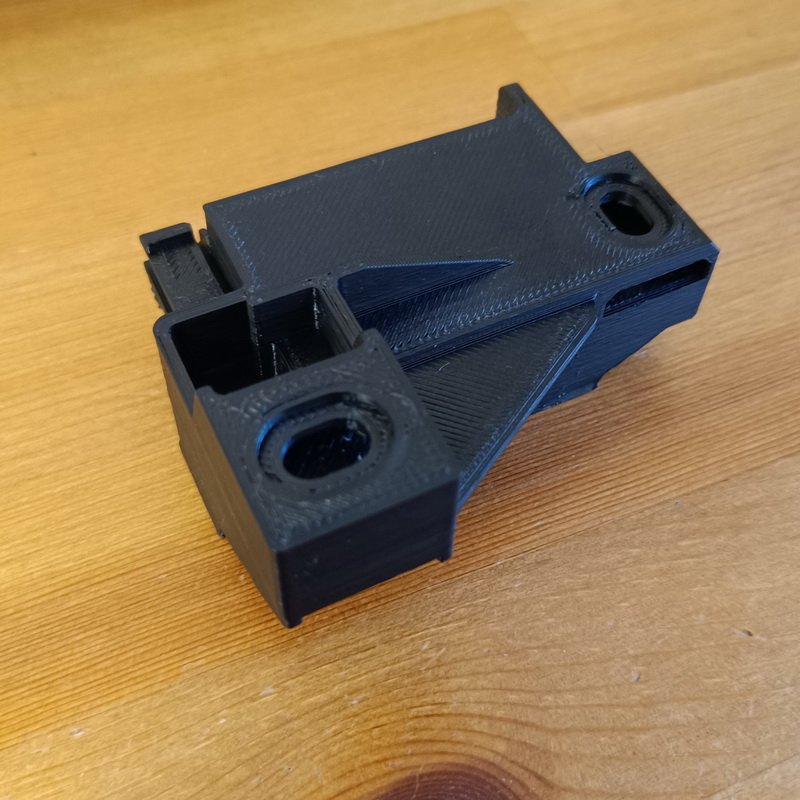

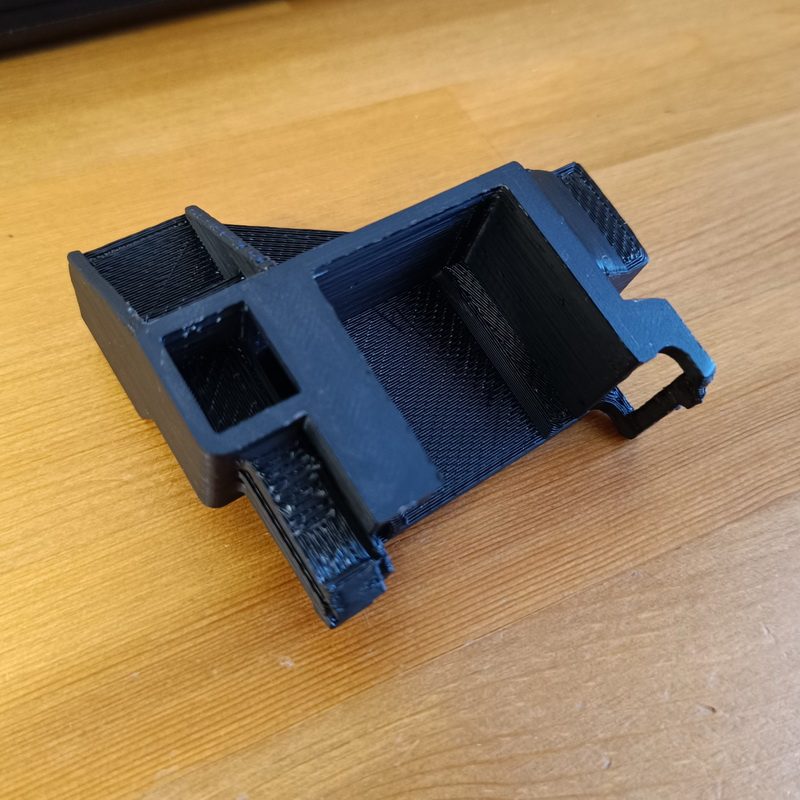

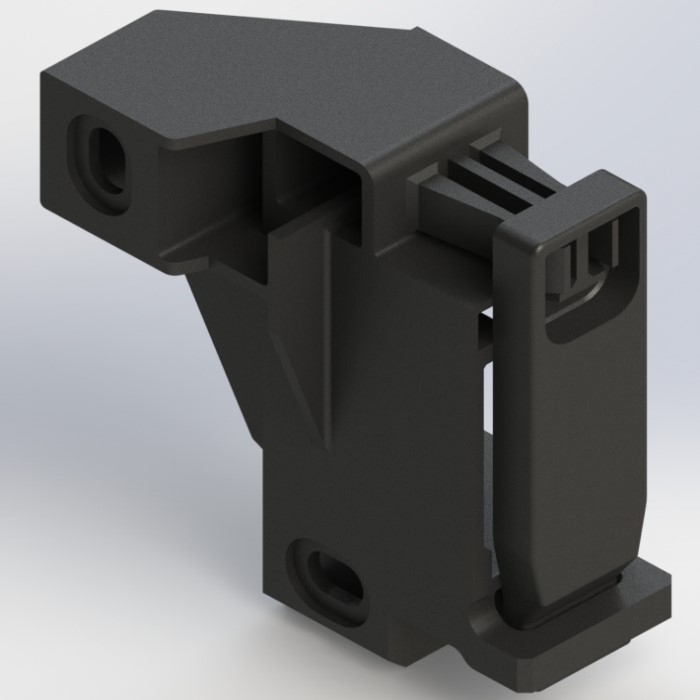

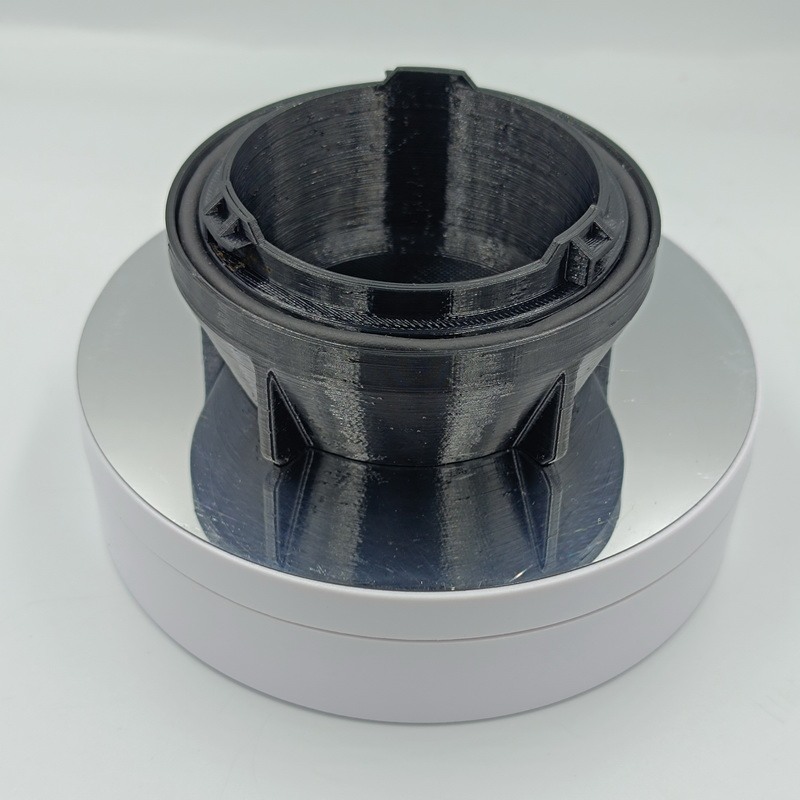

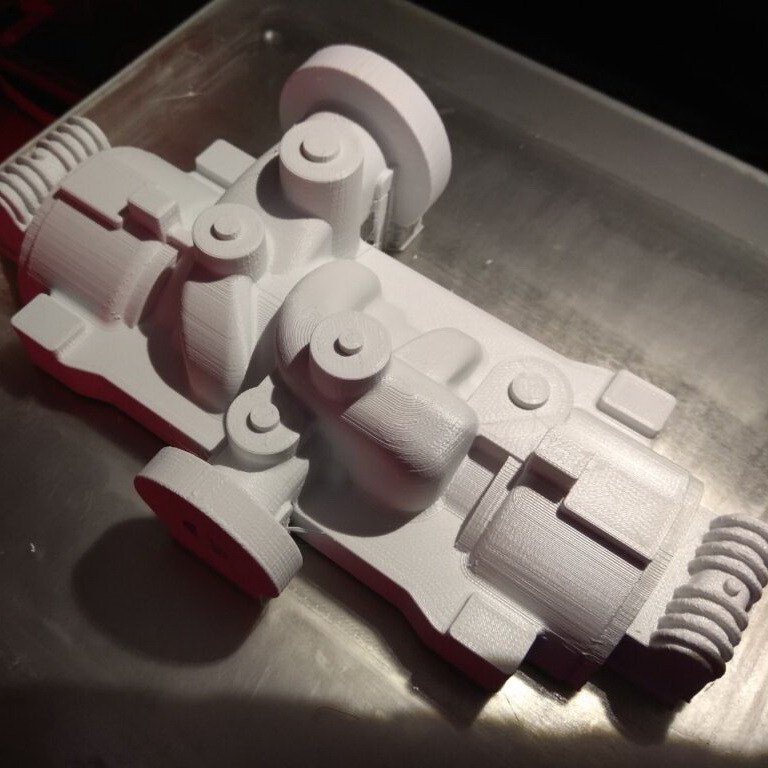

Gallery of parts printed using MJF technology

Resources on 3D printing using the MFJ method.

Order 3D printing online

CNC machine tools online

500+

3D-printers online:

100+

All downloads are secure and private