What is the manufacturability of the part. Design Manufacturability Analysis (DFM)

Introduction

Manufacturability of the part. What it is?

In the fast-paced world of manufacturing, precision and efficiency are paramount. As an online CNC machining platform, CNC-Shift understands the critical importance of ensuring that every part designed is not only innovative and functional but also manufacturable. This is where Design Manufacturability Analysis (DFM) comes into play. In this article, we will delve into the concept of manufacturability, explore the significance of DFM, and highlight its role in optimizing the production process to deliver superior results for our valued customers.

Understanding Manufacturability

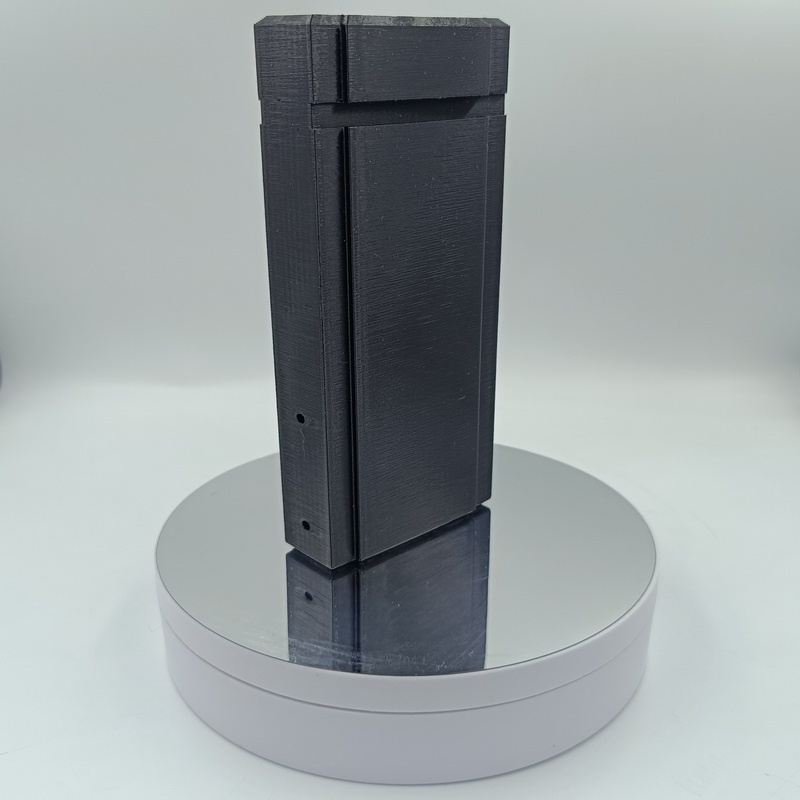

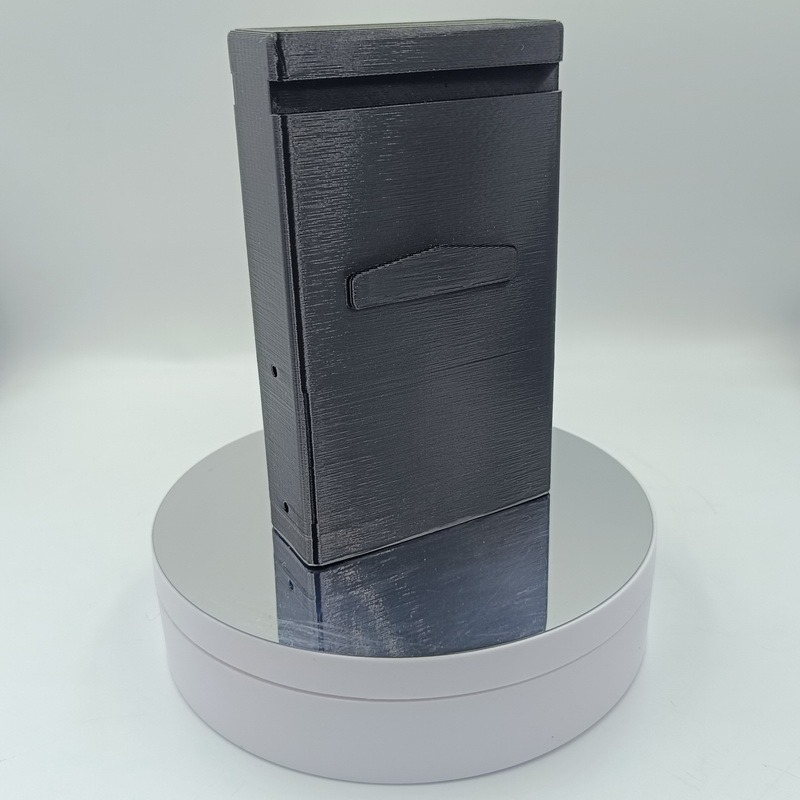

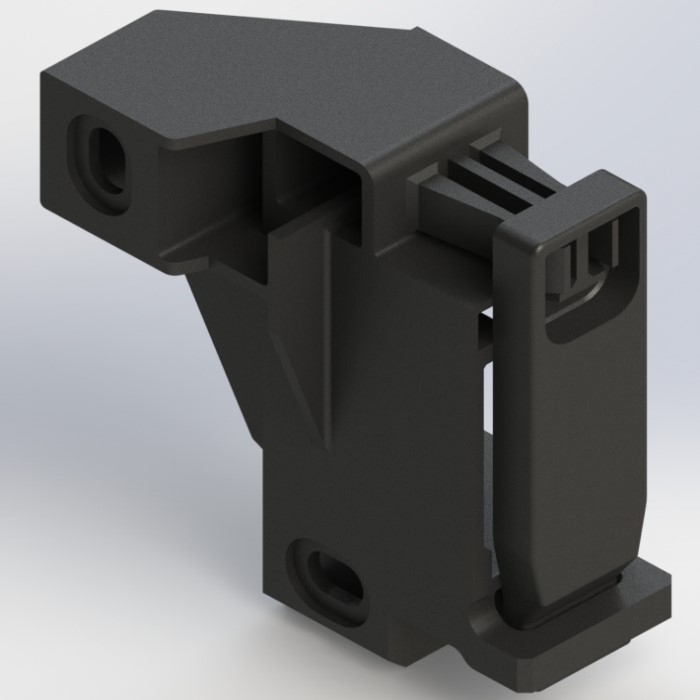

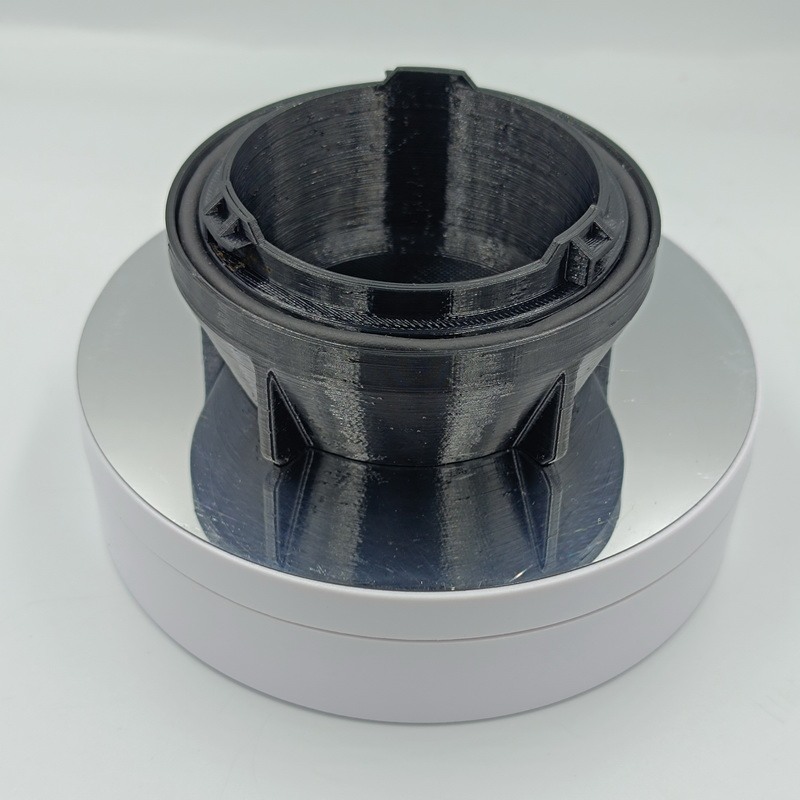

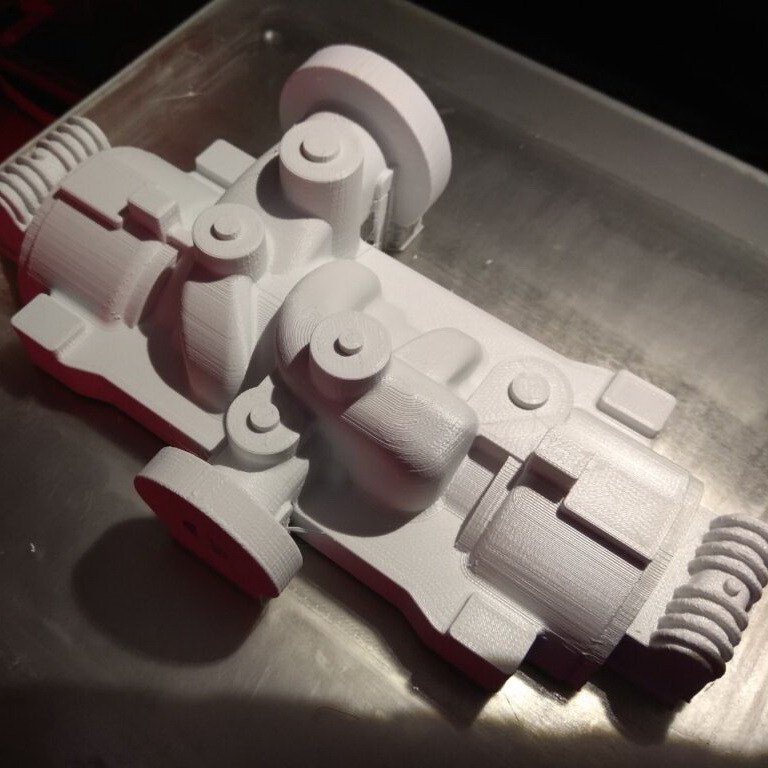

Manufacturability, in the context of CNC machining, refers to the ease and efficiency with which a designed part can be turned into a tangible product. It is the measure of how well a product’s design aligns with the capabilities and limitations of the manufacturing process. A part with good manufacturability can be produced with minimal cost, reduced lead times, and minimal risk of errors. On the contrary, a part with poor manufacturability may result in increased production costs, longer lead times, and potential design flaws.

The Role of Design Manufacturability Analysis (DFM)

Design Manufacturability Analysis (DFM) is a systematic approach used to assess and optimize the manufacturability of a part during the design phase. Its primary purpose is to collaborate with designers and engineers to ensure that the envisioned product can be manufactured efficiently, economically, and with the highest possible quality.

Key Factors Considered in DFM:

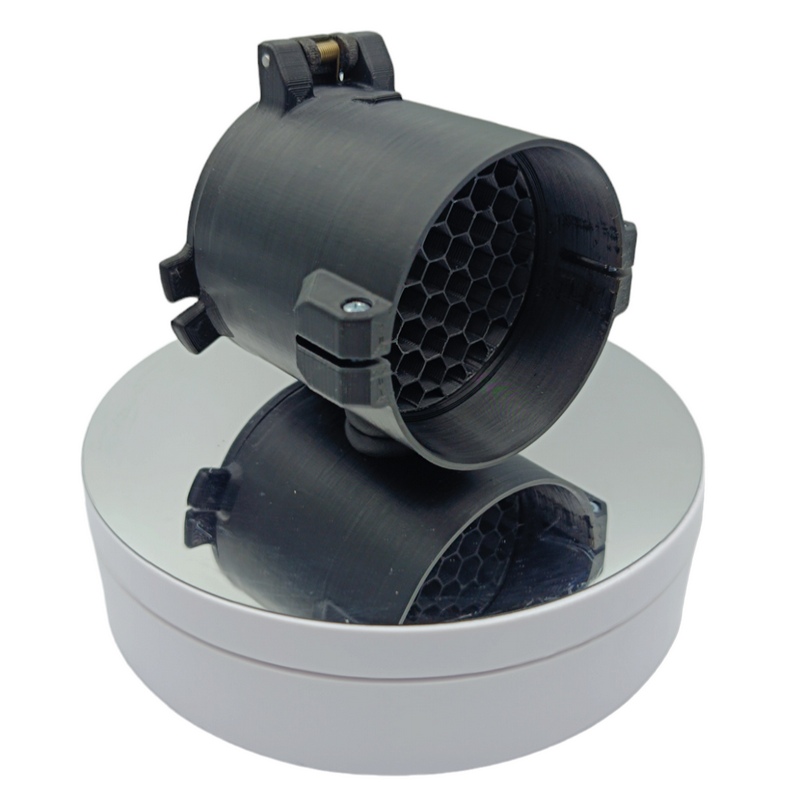

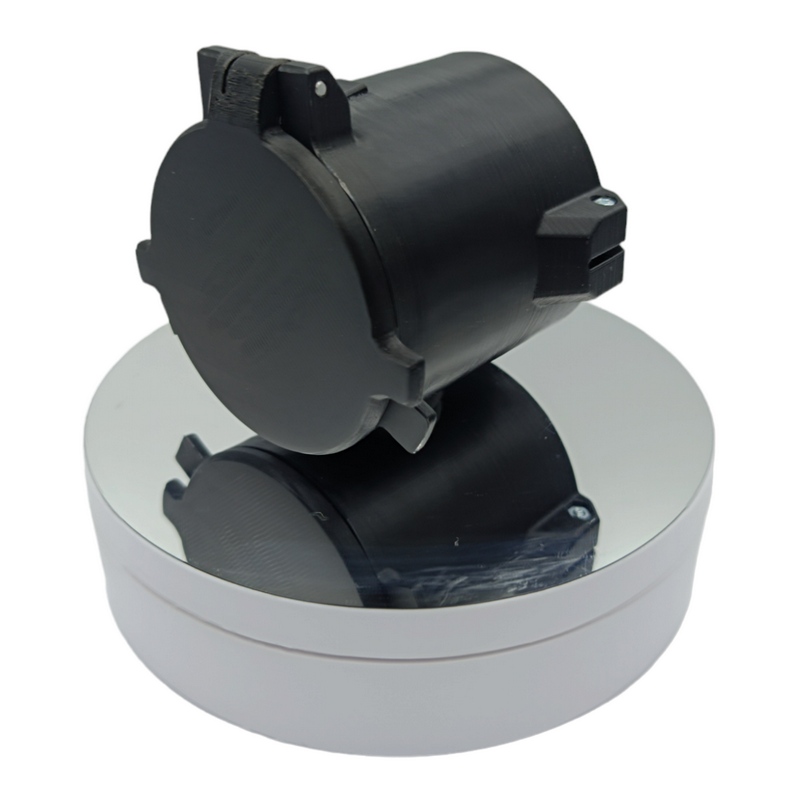

- Material Selection: The choice of materials directly impacts the manufacturability of a part. DFM assesses the availability, cost, and suitability of materials, considering factors like strength, durability, and machinability.

- Geometric Complexity: Intricate designs can pose challenges during production. DFM evaluates the part’s geometry to identify areas that might require specialized tools or processes.

- Tolerances and Fits: DFM scrutinizes the specified tolerances and fits to ensure they are feasible within the chosen manufacturing process.

- Tooling and Machining Processes: The selection of appropriate tools and machining processes can significantly impact efficiency and cost-effectiveness. DFM aids in optimizing these choices.

- Assembly Considerations: For parts intended for assembly into larger products, DFM evaluates how the design aligns with assembly requirements to streamline the overall production process.

- Design for Cost: DFM helps identify areas where design modifications can reduce production costs without compromising product quality or functionality.

Benefits of DFM Implementation

- Cost Reduction: By identifying potential issues early in the design phase, DFM helps prevent costly modifications and rework during manufacturing, leading to significant cost savings.

- Faster Time-to-Market: Streamlining the manufacturing process through DFM ensures faster production cycles and reduced lead times, enabling products to reach the market quicker.

- Improved Product Quality: By addressing potential manufacturing challenges proactively, DFM helps minimize defects and errors, resulting in higher-quality end products.

- Enhanced Collaboration: DFM fosters collaboration between designers, engineers, and manufacturers, facilitating a seamless exchange of ideas and expertise.

- Sustainable Manufacturing: Optimized manufacturability means less material waste, energy consumption, and environmental impact, aligning with sustainable manufacturing practices.

Conclusion

In conclusion, the manufacturability of a part is a crucial aspect of the CNC machining process. Design Manufacturability Analysis (DFM) plays a pivotal role in ensuring that the envisioned product can be manufactured efficiently and cost-effectively. By implementing DFM principles, CNC-Shift is committed to delivering superior results to its customers through streamlined production processes, reduced costs, and faster time-to-market, all while maintaining the highest standards of quality. Embracing DFM sets the foundation for successful collaboration between designers and manufacturers, ultimately leading to the creation of innovative and reliable products that excel in today’s competitive market.