Design for FDM 3D Printing – Tips

For successful 3D printing using Fused Deposition Modeling (FDM) technology, your 3D model needs to meet specific requirements to ensure accurate and high-quality printing. Key design considerations for 3D models intended for FDM 3D printing are as follows:

File Format

The 3D model should be in a format readable by the 3D printing software used by the FDM printer. The most common file formats for 3D printing are STL (Standard Tessellation Language) and OBJ (Object). Most 3D modeling software can export files in these formats.

Watertight Geometry

The 3D model must have watertight geometry, meaning it should be a completely enclosed solid object (shell) without any holes or gaps. If the model has any openings or gaps, the printing software may interpret it as a non-solid object, leading to incorrect printing.

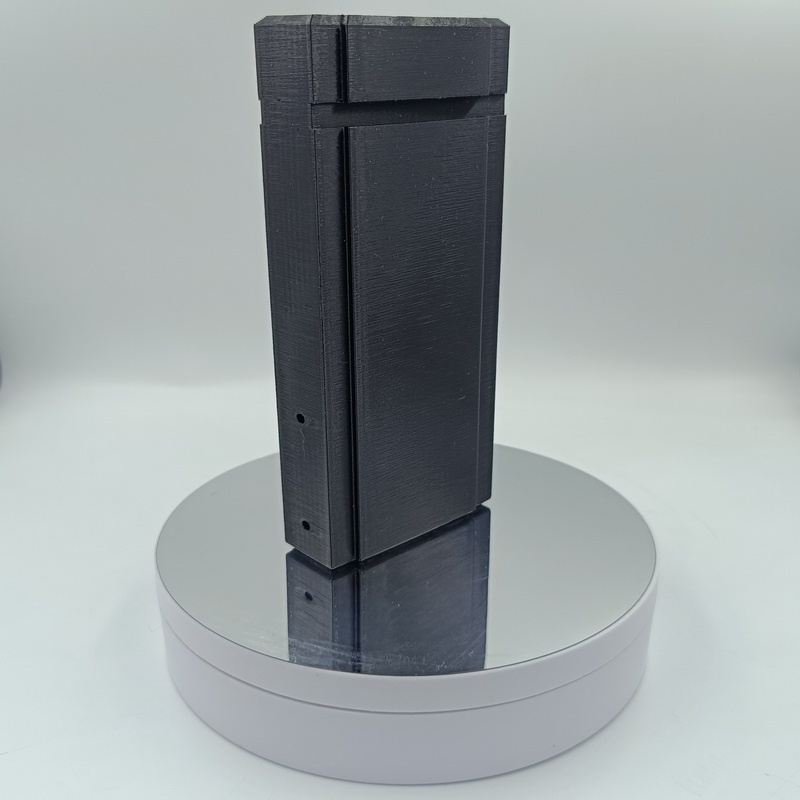

Correct Orientation

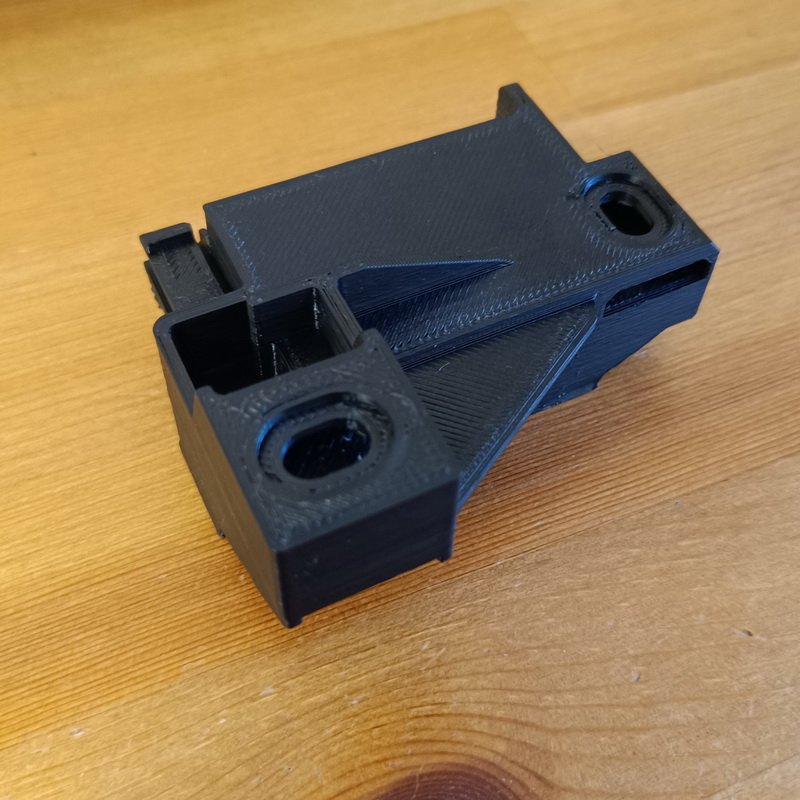

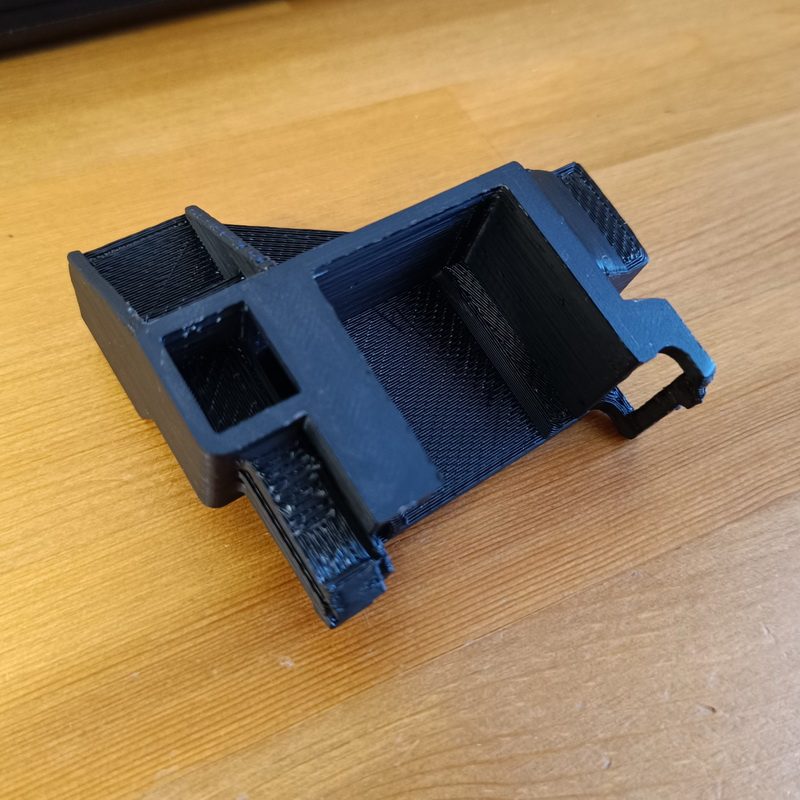

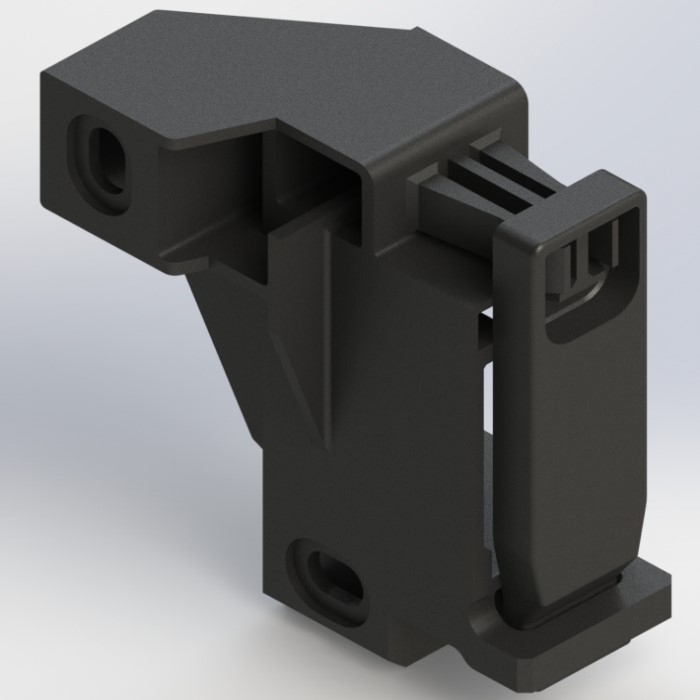

Proper orientation of the 3D model is necessary for accurate and high-quality printing. Usually, it’s best to orient the model to minimize the need for supports and ensure stability during printing. Models are often positioned to reduce the number of required supports, thus saving material.

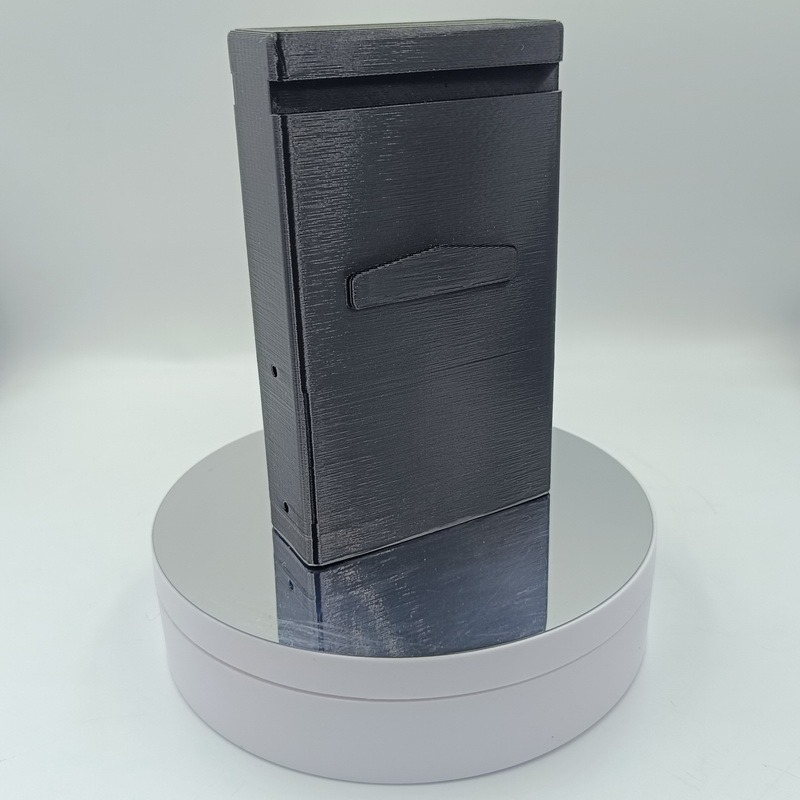

Wall Thickness

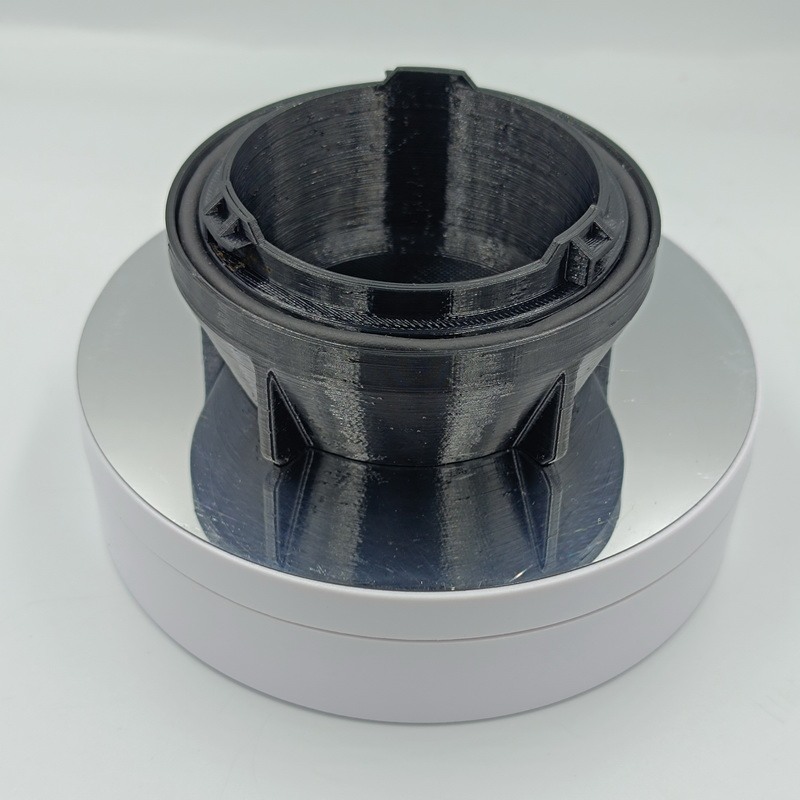

The wall thickness of the 3D model should be at least the size of the FDM printer’s nozzle diameter used for printing. If the walls are too thin, the model might be fragile and prone to breaking.

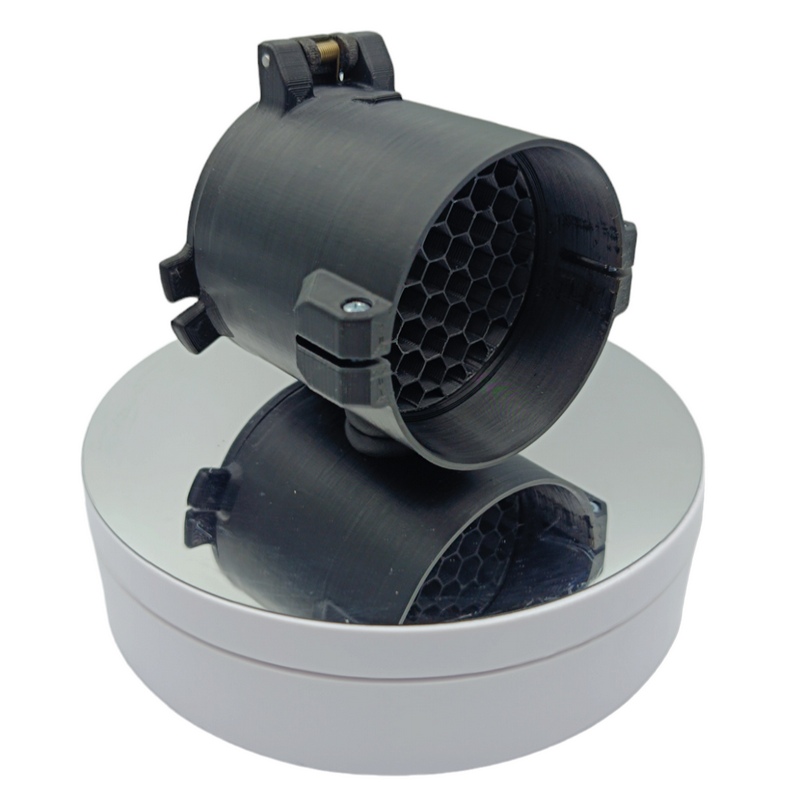

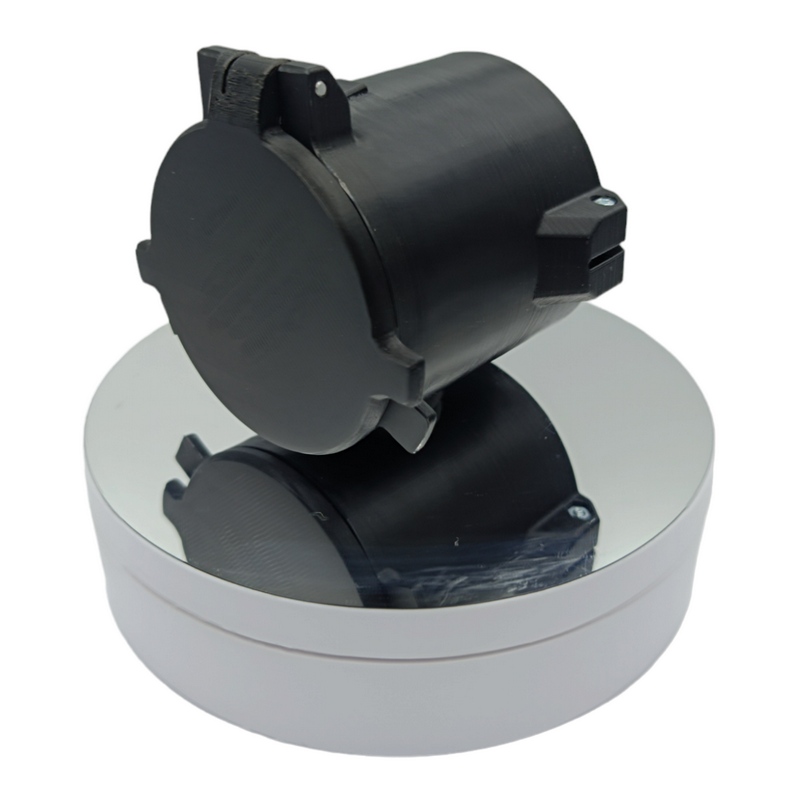

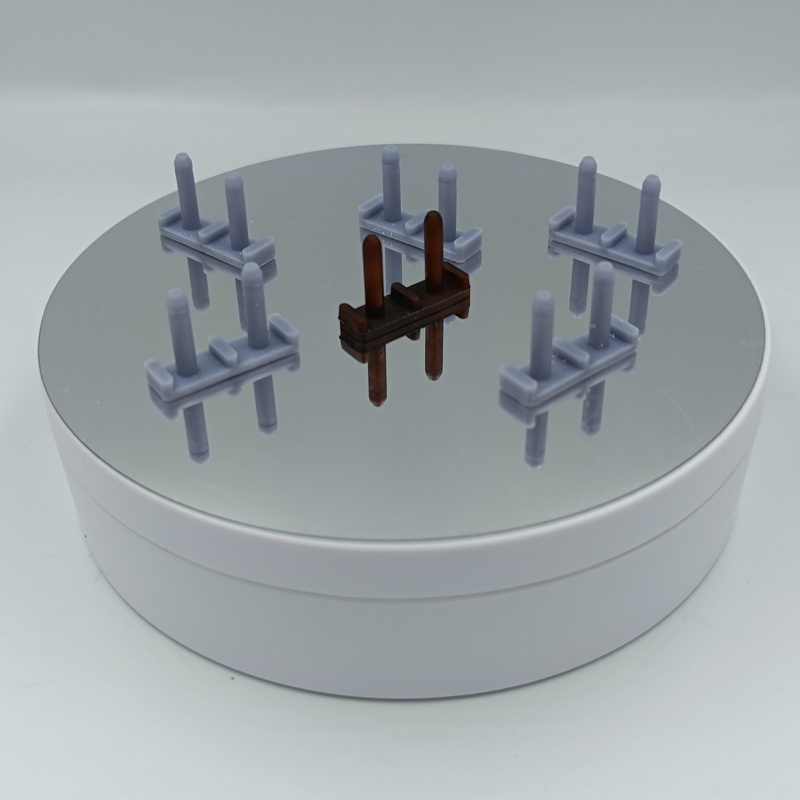

Overhangs and Supports

Overhangs are parts of the model that extend beyond the vertical boundary of the previous layer. Supports are required for overhangs to prevent sagging and ensure accurate model printing. Hence, the design should focus on minimizing overhangs and creating easily removable supports.

Layer Density

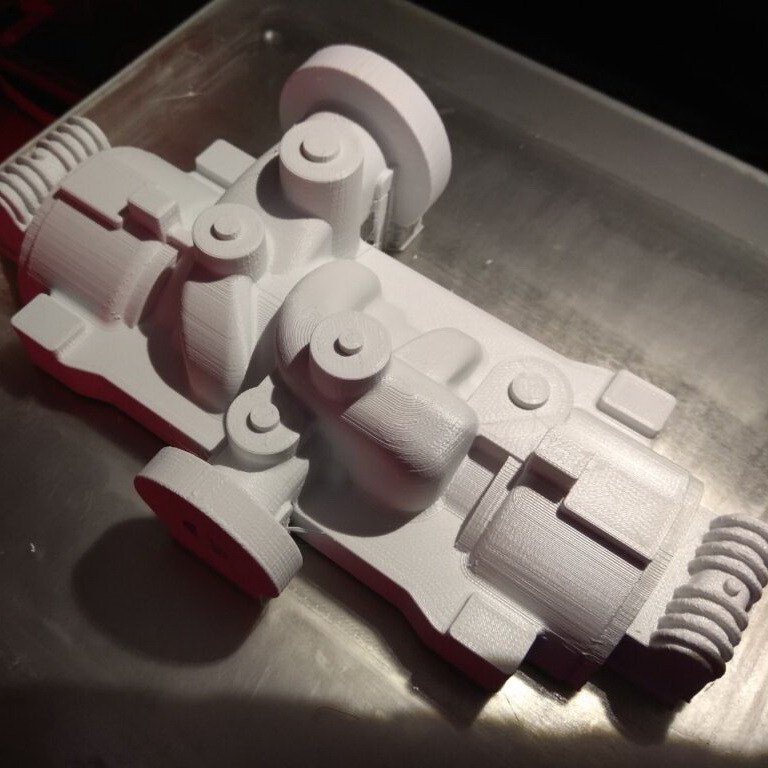

The layer density of the 3D model determines how much material is used to fill the interior of the model. The layer density should be appropriately set to ensure the model is strong enough for its intended use but not overly dense, which could lead to material waste and longer printing times.

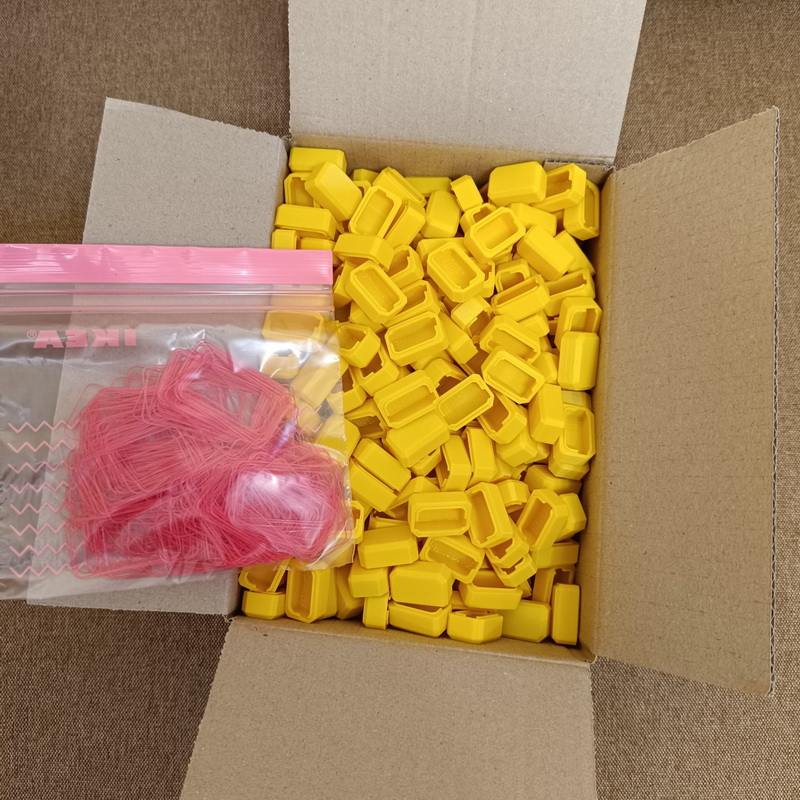

Material Choice

FDM printers can use various plastics, and the material choice can significantly impact the strength, rigidity, heat resistance, and other properties of the final part. It’s crucial to select the right material for the intended use of the model.

By ensuring that your 3D models adhere to these requirements, you can be confident that they can be accurately and high-quality printed using FDM 3D printing technology.