Dimensional Limits in CNC Machining. Design Considerations

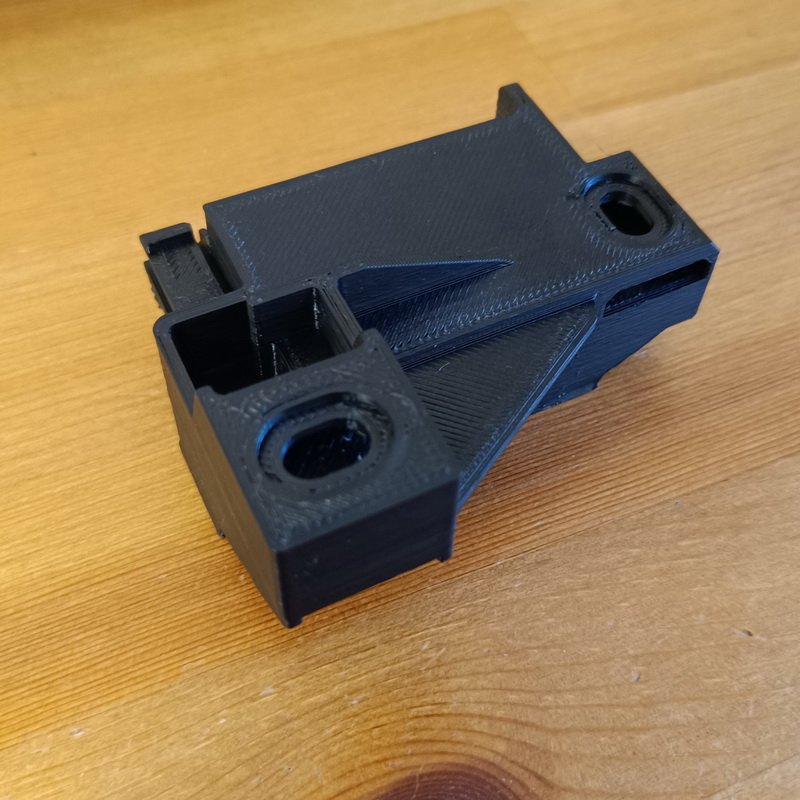

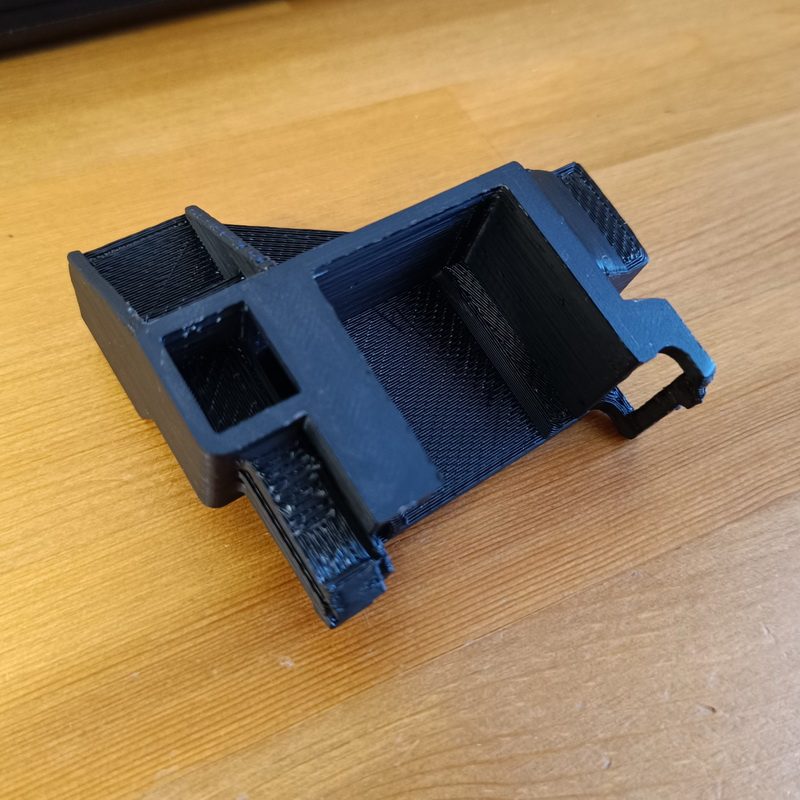

CNC machines have revolutionized the manufacturing industry, offering the capability to produce a wide range of complex and diverse products. However, Dimensional Limits in CNC Machining is something to consider when designing parts. Understanding these limitations will enable designers and engineers to create optimal designs that align with the capabilities of CNC machines and post-processing operations. Let’s explore some of the key size limitations in CNC machining and their impact on the design process.

CNC Milling Machine Work Envelope

The work envelope of a CNC milling machine defines the total area the machine can cover while moving in the X, Y, and Z axes. This work envelope determines the machine’s travel limitations, which, in turn, define the maximum part size it can produce. CNC Shift partner network includes CNC machining centers with substantial travel limits, such as up to 1,600 mm in the X-axis, 800 mm in the Y-axis, and 1000.2 mm in the Z-axis.

However, it’s essential to note that the travel limitations don’t always precisely specify the maximum part dimensions. Deep features requiring long tooling can reduce the effective work envelope of a machine. The Z travel of 900 mm doesn’t translate to a part height or depth of 900 mm. Depending on the part size and features, the Z height of the part must be less than 900 mm to allow for tool clearance.

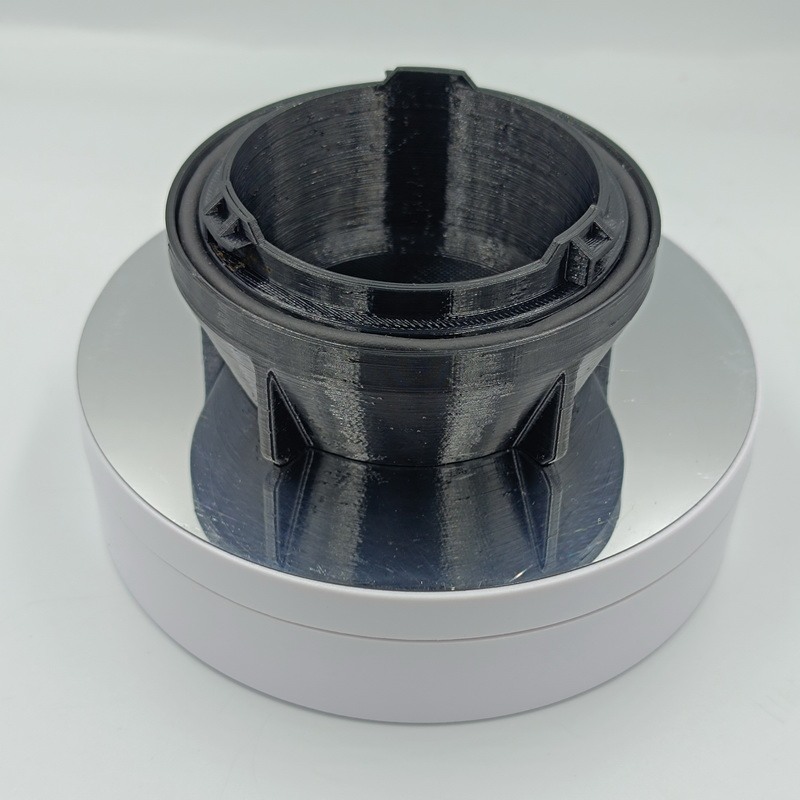

CNC Lathe Part Diameter and Length

For cylindrical parts manufactured on a lathe, the critical limiting dimensions are the part’s diameter and overall length. The maximum machinable length of a part depends on its diameter, and the diameter-to-length ratio determines part balance and stability during machining.

CNC Shift lathe capabilities can produce parts of up to 450 mm in diameter. However, for parts with diameters larger than 450 mm, special considerations may be required. Our network includes companies offering live tooling lathes that reduce machining time and can handle more complex turned parts with off-axis features. However, this may lead to smaller effective work envelopes.

Impact on Post-Processing Operations

Part size also influences the availability of various post-processing operations. For instance, larger parts may not fit into media-blasting cabinets, making blasting unfeasible. Moreover, large parts requiring anodizing or electroplating might necessitate custom racking to accommodate their size.

Summary

In summary, understanding the work envelope of CNC machines is crucial as it determines the maximum part size achievable. For parts manufactured on a lathe, the diameter and length are vital limiting dimensions. Additionally, part size plays a significant role in determining the available post-processing operations. By considering these size limitations during the design phase, designers can optimize their designs to ensure seamless CNC machining and efficient post-processing.

Congratulations! You’re now equipped to create parts that align with our partner network’s machine sizes. For more design tips and valuable resources on CNC machining, visit our CNC machining resources portal or request an instant CNC machining quote now. Our online CNC machining platform is dedicated to delivering top-notch results for your diverse manufacturing needs.